Understanding the Pull Pin Spring Mechanism

November 9, 2024Pull Pin Springs are small but mighty components found in a variety of applications, from grenades and fire extinguishers to everyday items like keychains and lanyards. These ingenious devices utilize a simple yet effective mechanism to secure a pin in place until intentionally released. This article will delve into the intricacies of pull pin springs, exploring their functionality, diverse applications, and the key considerations for selecting the right spring for your specific needs.

Pull down maps for sale might seem unrelated, but understanding mechanical principles like those found in pull pin springs can be beneficial in various fields. Let’s explore the core principles behind these essential components.

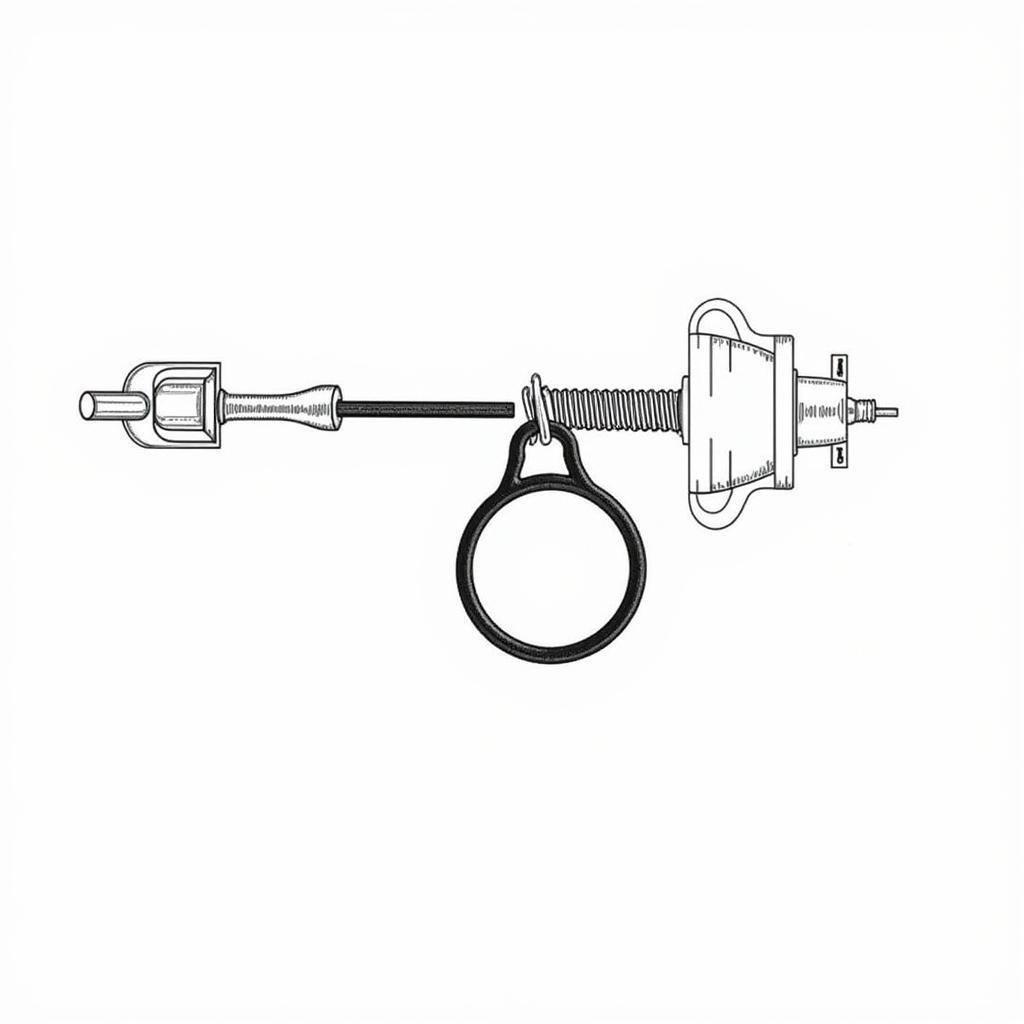

How Does a Pull Pin Spring Work?

The magic of a pull pin spring lies in its clever design. Typically, a pull pin spring consists of a coiled spring, often made of stainless steel for durability and corrosion resistance, wrapped around a central pin. This pin is then inserted into a housing or receptacle, effectively locking it in place. The spring exerts pressure against the pin, preventing it from accidentally slipping out. To release the pin, a ring or handle attached to the spring is pulled, compressing the spring and allowing the pin to be removed. This simple action provides a reliable and secure locking mechanism until the desired moment of release.

Key Components of a Pull Pin Spring

- The Spring: The coiled spring is the heart of the mechanism, providing the necessary tension to hold the pin securely.

- The Pin: This is the component being secured by the spring. Its dimensions and material are crucial for proper functionality.

- The Housing/Receptacle: This is the part that the pin fits into, providing a stable and secure anchor point.

- The Ring/Handle: This component allows the user to easily pull and compress the spring, releasing the pin.

Pull Pin Spring Mechanism Diagram

Pull Pin Spring Mechanism Diagram

Applications of Pull Pin Springs

Pull pin springs are incredibly versatile and are employed in a wide range of applications across various industries:

- Safety and Security: Fire extinguishers, grenades, and safety harnesses rely on pull pin springs for quick and reliable release mechanisms.

- Aerospace and Defense: These springs are crucial components in ejection seats and other critical safety systems.

- Industrial Equipment: Pull pin springs are used in machinery and equipment to secure components and prevent accidental operation.

- Consumer Products: Keychains, lanyards, and even some toys utilize pull pin springs for their convenient and secure fastening capabilities.

St. Louis Cardinals fleece material could even potentially benefit from the incorporation of a pull pin spring mechanism for added functionality and design elements. Imagine a pull pin spring securing a detachable hood or pocket – the possibilities are vast!

Selecting the Right Pull Pin Spring

Choosing the correct pull pin spring requires careful consideration of several factors:

- Spring Force: The amount of force required to compress the spring and release the pin.

- Pin Diameter: The size of the pin will determine the size of the spring and housing required.

- Material: Stainless steel is a popular choice due to its durability and resistance to corrosion.

- Environment: The operating environment will influence the choice of material and spring coating.

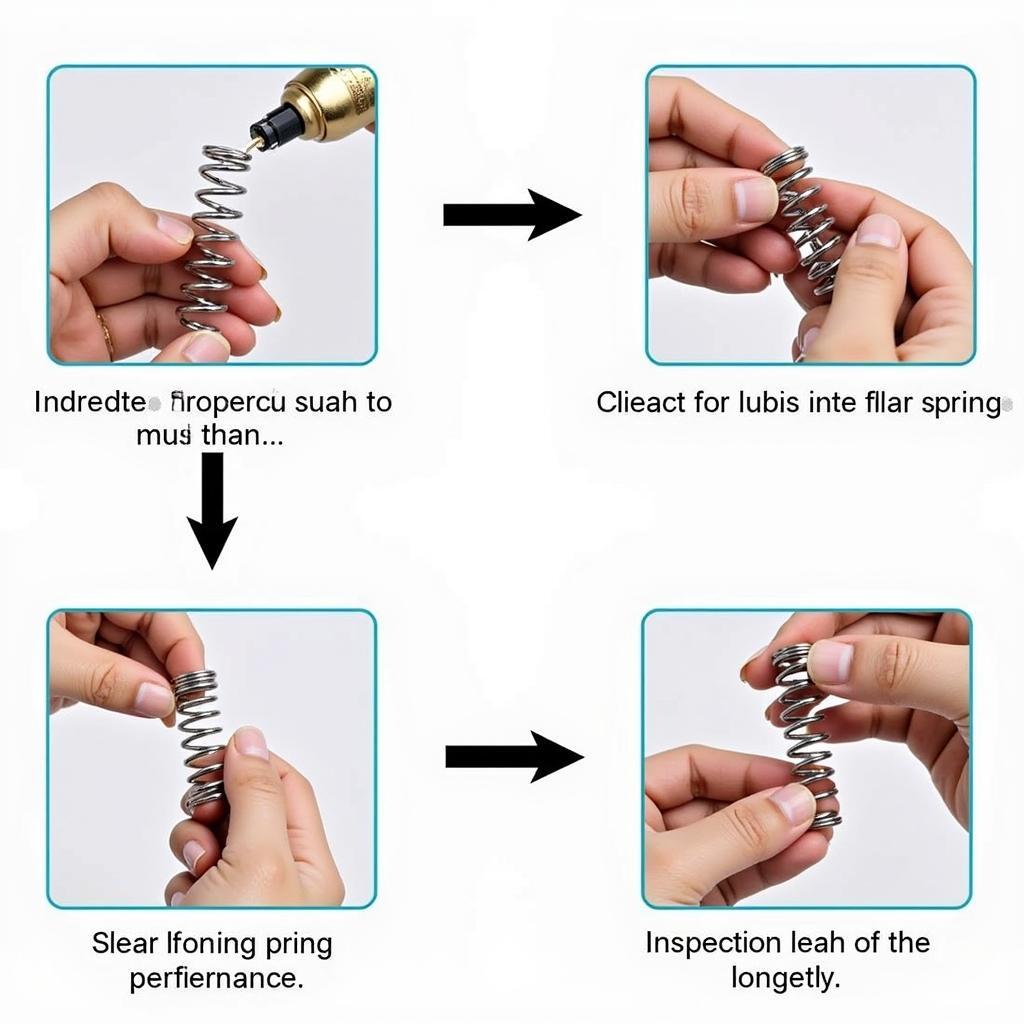

Pull Pin Spring Maintenance and Troubleshooting

While pull pin springs are generally robust and reliable, occasional maintenance and troubleshooting might be necessary:

- Lubrication: Regular lubrication can help prevent corrosion and ensure smooth operation.

- Inspection: Periodically inspect the spring for signs of wear, damage, or corrosion.

- Replacement: If the spring is damaged or worn, it should be replaced immediately.

Looking for a 3 4 mini bike clutch? Understanding the principles of mechanical components like pull pin springs can be beneficial in choosing and maintaining various parts for motorized vehicles.

Pull Pin Spring Maintenance Tips

Pull Pin Spring Maintenance Tips

Conclusion

Pull pin springs are essential components in countless applications, providing a simple yet effective solution for securing and releasing pins. Understanding their functionality, various types, and key selection criteria ensures optimal performance and reliability. By choosing the right pull pin spring and performing regular maintenance, you can maximize its lifespan and ensure it continues to function effectively. Remember, a small spring can make a big difference!

FAQs

-

What materials are pull pin springs typically made of?

Stainless steel is a common choice due to its durability. -

How do I choose the right spring force for my application?

Consider the weight and size of the object being secured. -

What are the common signs of a worn-out pull pin spring?

Look for signs of corrosion, deformation, or difficulty in compressing the spring. -

Can I lubricate a pull pin spring?

Yes, lubrication can help prevent corrosion and ensure smooth operation. -

Where can I find pull pin springs for sale?

Various online retailers and industrial suppliers offer a wide selection. -

What are the safety precautions when handling pull pin springs?

Always handle with care to avoid injury.

If you’re interested in smoking poles, understanding the mechanics of different locking and release mechanisms can be a valuable asset.

Need Help?

For further assistance or inquiries, please don’t hesitate to contact us:

Phone: 0963418788

Email: [email protected]

Address: 2M4H+PMH, Phường Nghĩa Thành, Gia Nghĩa, Đắk Nông, Việt Nam

We have a 24/7 customer support team ready to assist you.

Perhaps you might also be interested in men’s red fedora hats. Check out our selection!