Peel and Stick Diamond Plate: The DIY Solution for Durable Surfaces

October 13, 2024Peel And Stick Diamond Plate is a versatile and cost-effective solution for adding a durable, non-slip surface to a variety of areas. This self-adhesive material is easy to install, making it a popular choice for both homeowners and professionals alike. Whether you’re looking to enhance safety, protect surfaces, or simply add a touch of industrial style, peel and stick diamond plate offers a practical and aesthetically pleasing option.

Understanding Peel and Stick Diamond Plate

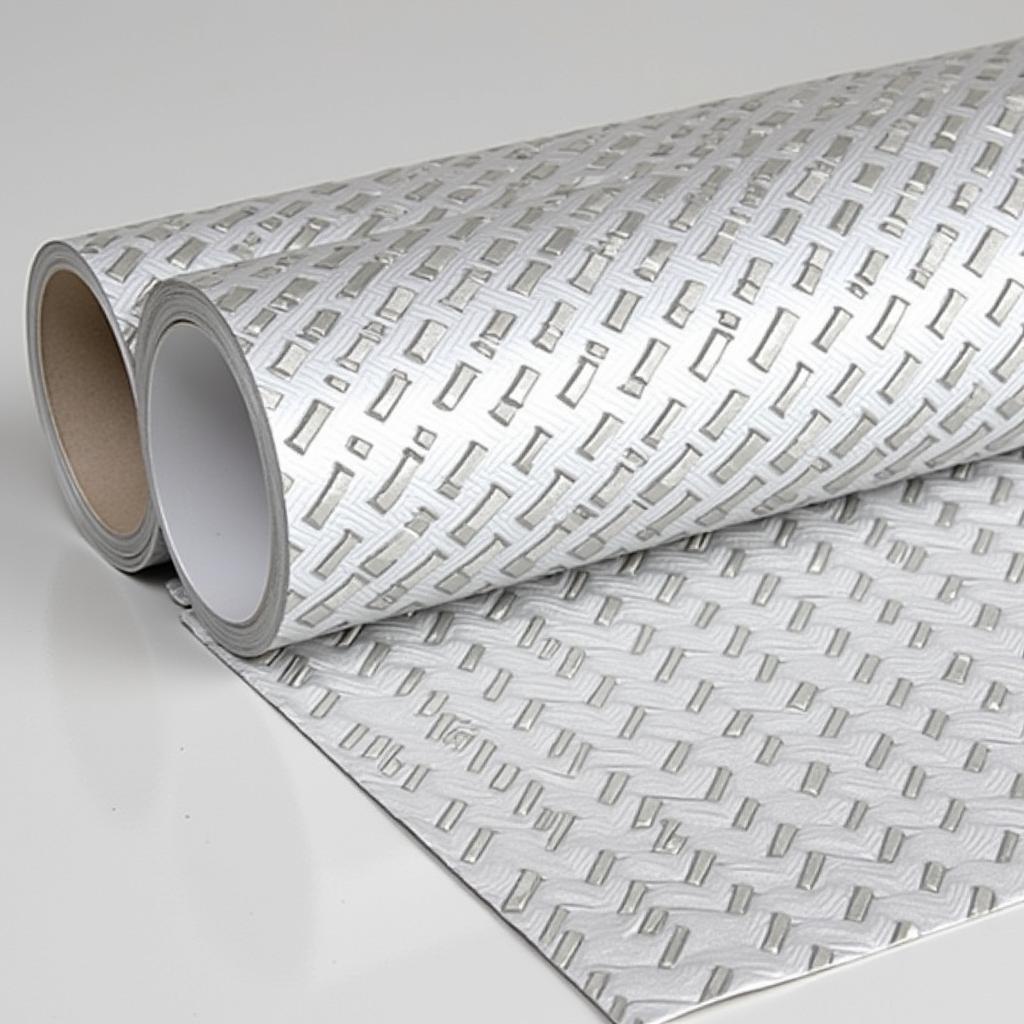

Close-up of peel and stick diamond plate material

Close-up of peel and stick diamond plate material

Peel and stick diamond plate is a thin sheet of material, typically made from aluminum or PVC, that features a raised diamond pattern. This pattern provides excellent traction, making it ideal for use in areas prone to slipping hazards. The back of the material is coated with a strong adhesive that allows for easy application to a variety of surfaces, including wood, metal, concrete, and more.

Advantages of Using Peel and Stick Diamond Plate

The popularity of peel and stick diamond plate stems from its numerous advantages:

- Ease of Installation: One of the most significant benefits is its straightforward application. Simply peel off the backing and press the material firmly onto the prepared surface.

- Durability: Despite its thin profile, peel and stick diamond plate is surprisingly durable. It’s resistant to abrasion, impacts, and many chemicals, making it suitable for high-traffic areas.

- Versatility: This material can be used for a wide range of applications, both indoors and outdoors.

- Cost-Effective: Compared to traditional diamond plate, the peel and stick option offers a budget-friendly solution without compromising on quality or functionality.

Common Applications of Peel and Stick Diamond Plate

The versatility of peel and stick diamond plate makes it suitable for a wide range of applications, including:

- Stair Treads and Ramps: Improve safety on stairs, ramps, and inclines by providing a non-slip surface, especially in areas exposed to rain or moisture.

- Tool Boxes and Workbenches: Protect surfaces from scratches, dents, and spills while adding a professional, organized look to workspaces.

- Vehicle Interiors: Line truck beds, van floors, and other vehicle surfaces to prevent cargo from shifting and protect against wear and tear.

- Flooring: Create durable, easy-to-clean flooring for workshops, garages, and other areas subject to heavy use.

Tips for Successful Installation

While installing peel and stick diamond plate is relatively simple, following these tips can help ensure optimal results:

- Surface Preparation: Ensure the surface is clean, dry, and free of any dust, debris, or grease.

- Accurate Measurements: Measure the area to be covered precisely to avoid unnecessary cuts or waste.

- Gradual Application: Peel back a small section of the backing paper at a time and carefully align the material before pressing it firmly onto the surface.

- Avoid Air Bubbles: Use a roller or a smoothing tool to press out any air bubbles as you apply the material.

- Sealing Edges (Optional): For added durability and moisture resistance, consider applying a sealant along the edges of the installed diamond plate.

Conclusion

Peel and stick diamond plate offers a practical and convenient way to enhance the safety, durability, and aesthetics of various surfaces. Its ease of installation, affordability, and wide range of applications make it a valuable tool for DIY enthusiasts and professionals alike. When choosing peel and stick diamond plate, consider the intended application and the environment to select the most suitable material and thickness for your needs.