Understanding Long Neck Grommets

November 8, 2024Long Neck Grommets are essential components in various applications, offering a secure and durable solution for managing cables, wires, and hoses. They provide a protective passage, preventing abrasion and damage while maintaining a clean and organized appearance. Choosing the right long neck grommet depends on several factors, including the size and type of material being passed through, the environment it will be used in, and the desired aesthetic finish.

What are Long Neck Grommets and Why are They Important?

Long neck grommets, also known as extended neck grommets, are similar to standard grommets but feature an elongated neck. This extended neck provides added protection and flexibility for applications where cables or wires need to be routed at an angle or require extra clearance. They are crucial in protecting against sharp edges and preventing chafing, ultimately extending the lifespan of the wires and hoses they accommodate.

Imagine, for example, the wiring in a car. Without proper protection, constant vibration and friction against metal edges could quickly wear down the insulation, leading to short circuits and potential malfunctions. Long neck grommets act as a crucial barrier, preventing these issues and ensuring the electrical system’s longevity. This same principle applies across various industries, from electronics and automotive to marine and industrial equipment.

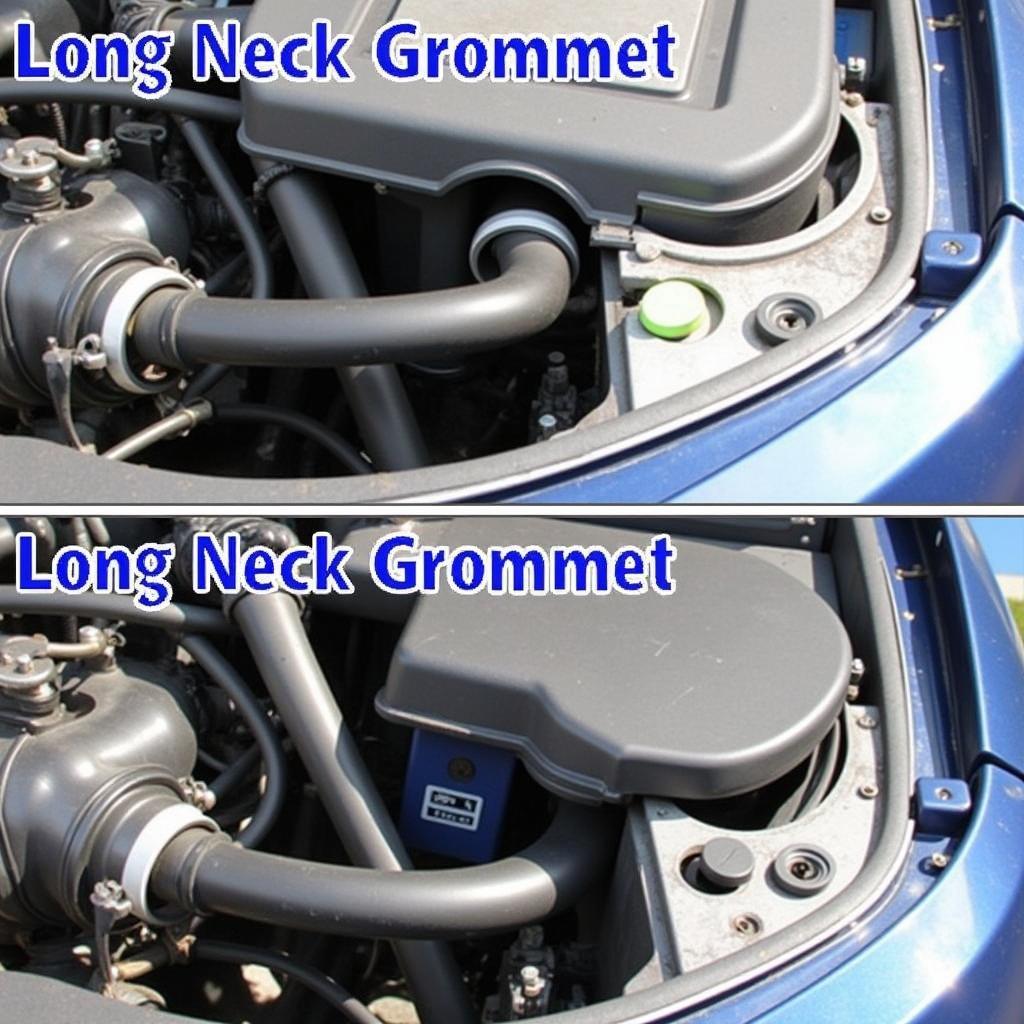

Long Neck Grommet Used in an Automotive Application

Long Neck Grommet Used in an Automotive Application

Different Types and Materials of Long Neck Grommets

Long neck grommets are available in a variety of materials to suit different application requirements. Common materials include rubber, plastic, metal, and silicone. Each material offers specific advantages:

- Rubber: Excellent flexibility and resistance to abrasion, making them ideal for applications involving vibration and movement.

- Plastic: Cost-effective and lightweight, suitable for less demanding environments. Different types of plastic offer varying degrees of durability and temperature resistance.

- Metal: Provides superior strength and durability, ideal for harsh environments or applications with heavy cables.

- Silicone: Offers excellent heat and chemical resistance, suitable for high-temperature applications or environments with exposure to chemicals.

Understanding the characteristics of each material is crucial for selecting the appropriate long neck grommet for a specific application.

How to Choose the Right Long Neck Grommet Size?

Choosing the correct size is paramount for optimal functionality and protection. The key measurements include the inner diameter (ID), outer diameter (OD), and neck length. The ID should be slightly larger than the diameter of the cable or wire being passed through, allowing for a snug fit without causing compression or damage. The OD determines the size of the hole required for installation, while the neck length provides the necessary clearance and flexibility for angled routing.

Installing Long Neck Grommets: A Step-by-Step Guide

- Determine the required size: Measure the diameter of the cable or wire and select a grommet with a slightly larger ID.

- Prepare the surface: Ensure the surface is clean and free from debris.

- Create the hole: Drill or punch a hole of the appropriate size based on the grommet’s OD.

- Insert the grommet: Push the grommet into the hole, ensuring it is securely seated.

- Route the cable or wire: Carefully feed the cable or wire through the grommet’s neck.

Proper installation is crucial for ensuring the long neck grommet provides optimal protection and performance.

Benefits of Using Long Neck Grommets

- Protection from abrasion: The extended neck shields cables and wires from sharp edges and rough surfaces, preventing damage and extending their lifespan.

- Improved organization: Long neck grommets help keep cables and wires neatly organized, reducing clutter and improving overall aesthetics.

- Enhanced safety: By protecting wires from damage, long neck grommets reduce the risk of short circuits and other electrical hazards.

- Increased durability: They protect vulnerable areas of cables and wires, extending their lifespan and reducing the need for replacements.

“Using the right grommet can mean the difference between a reliable system and a constant headache,” says Johannes Van der Merwe, a Senior Electrical Engineer at Amsterdam Electronics.

Conclusion

Long neck grommets are invaluable components in various applications, providing essential protection and organization for cables, wires, and hoses. Choosing the right size and material is crucial for optimal performance, and proper installation ensures long-lasting protection and a clean, professional finish. Investing in quality long neck grommets is a small price to pay for the long-term benefits they offer in terms of safety, durability, and overall system reliability.

FAQ

- What is the difference between a standard grommet and a long neck grommet?

- What materials are long neck grommets made of?

- How do I choose the correct size long neck grommet?

- How do I install a long neck grommet?

- What are the benefits of using long neck grommets?

- Where can I buy long neck grommets?

- What industries commonly use long neck grommets?

For further assistance, please contact Phone Number: 0963418788, Email: [email protected] Or visit us at: 2M4H+PMH, Phường Nghĩa Thành, Gia Nghĩa, Đắk Nông, Việt Nam. We have a 24/7 customer service team.