Understanding the Importance of an Epi Spring

October 18, 2024An Epi Spring, short for epicyclic spring, plays a crucial role in various mechanical systems, particularly in clutches and brakes. These compact and powerful springs provide the necessary force to engage and disengage these systems smoothly and efficiently. Whether you’re a car enthusiast, a DIY mechanic, or simply curious about how things work, understanding the function and importance of an epi spring can be quite insightful.

What is an Epi Spring and How Does it Work?

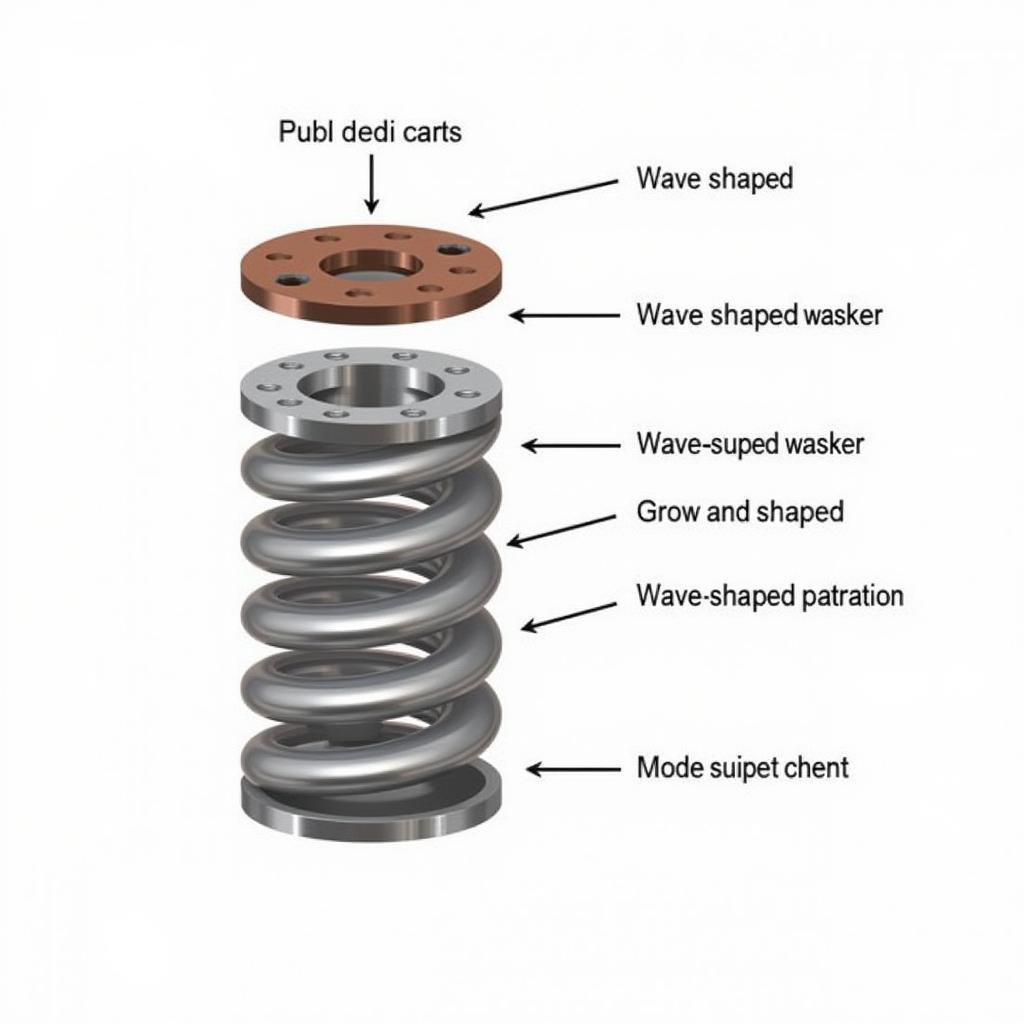

Unlike traditional coil springs that rely on compression or extension, an epi spring operates on a unique principle. It consists of one or more wave-shaped washers, typically made of spring steel, nested concentrically. When force is applied, these washers deform radially, storing potential energy. Releasing this force allows the washers to return to their original shape, releasing the stored energy and creating a spring force.

Epi Spring Mechanism

Epi Spring Mechanism

This distinctive mechanism offers several advantages over traditional coil springs, making epi springs ideal for specific applications:

- Compact Design: Epi springs can generate significant force within a very compact space, making them suitable for applications where space is limited, such as in clutches and brakes.

- High Force in a Small Package: They can exert higher forces compared to coil springs of similar size, due to their unique geometry and material properties.

- Variable Spring Rate: The force exerted by an epi spring can be easily adjusted by changing the number of waves in the washers or by combining multiple springs, providing design flexibility.

- Durability and Longevity: Epi springs are known for their durability and resistance to fatigue, ensuring a longer lifespan and reliable performance in demanding conditions.

Applications of Epi Springs

Epi springs are commonly found in various mechanical devices, including:

- Clutches: In motorcycle and automotive clutches, epi springs provide the necessary force to engage and disengage the clutch plates, ensuring smooth gear changes. The Hilliard clutch spring chart offers a comprehensive overview of different spring rates for various clutch applications.

- Brakes: Epi springs can be used in braking systems to provide the return force for brake calipers, ensuring quick and reliable brake pad retraction after the brake pedal is released.

- Valves: They are used in valves to control fluid flow, providing the force needed to open and close the valve mechanism precisely.

- Electrical Contacts: Epi springs ensure firm and consistent contact pressure in electrical connectors and switches, improving conductivity and reliability.

Advantages of Using Epi Springs

The unique characteristics of epi springs offer distinct advantages:

- Space Savings: Their compact size makes them ideal for applications where space is limited.

- High Force Capacity: They deliver a high force-to-size ratio, enabling powerful performance in compact devices.

- Design Flexibility: The variable spring rate allows for customization and fine-tuning for specific applications.

- Long Service Life: Epi springs are durable and resistant to fatigue, ensuring reliable and long-lasting performance.

- Smooth Operation: They provide smooth and consistent force delivery, resulting in quiet and efficient operation.

Choosing the Right Epi Spring

Selecting the correct epi spring is crucial for optimal performance and durability. Factors to consider include:

- Load Requirements: Determine the amount of force required for your specific application.

- Space Constraints: Measure the available space to ensure the spring fits properly.

- Operating Environment: Consider factors like temperature, humidity, and exposure to chemicals that may affect the spring’s performance.

- Material: Choose a spring material that can withstand the operating conditions and provide the necessary corrosion resistance.

Various Applications of Epi Springs

Various Applications of Epi Springs

Conclusion

Epi springs, with their unique design and exceptional force capabilities, play a vital role in numerous mechanical applications. Understanding their functionality and advantages allows for informed decisions when selecting components for clutches, brakes, and other critical systems. By leveraging the benefits of epi springs, engineers and designers can create more compact, efficient, and reliable mechanical devices.

For those looking to explore the versatility of springs further, the upcoming Doritos Spring Challenge promises to be an exciting event showcasing innovative engineering solutions. Whether you’re a seasoned engineer or simply fascinated by mechanical design, epi springs offer a glimpse into the world of compact yet powerful components driving innovation in various industries.

FAQs about Epi Springs

1. What are epi springs made of?

Epi springs are typically made of high-carbon spring steel for its excellent strength and elasticity.

2. How long do epi springs last?

Epi springs are known for their durability and can last for a significant number of cycles, often exceeding the lifespan of the devices they are used in.

3. Can epi springs be used in high-temperature environments?

Yes, certain types of epi springs are designed to withstand high temperatures, often used in automotive and aerospace applications.

4. Are epi springs expensive?

Epi springs are generally cost-effective, especially considering their high force capacity and long lifespan.

5. Where can I buy epi springs?

Epi springs can be purchased from specialized spring manufacturers and distributors, as well as online retailers.

Need Help? Contact Us!

If you need assistance with selecting the right epi spring for your application or have any questions about our products, feel free to contact us. Our team of experts is available 24/7 to provide guidance and support.

Phone: 0963418788

Email: [email protected]

Address: 2M4H+PMH, Phường Nghĩa Thành, Gia Nghĩa, Đắk Nông, Việt Nam.