Understanding Drop Pipe Elevators

November 8, 2024Drop Pipe Elevators are a critical component in many industrial processes, efficiently transporting bulk materials vertically. They offer a reliable and cost-effective solution for moving materials like grain, feed, and other granular products between different levels of a facility. This article delves into the intricacies of drop pipe elevators, exploring their functionality, benefits, applications, and key considerations for optimal performance.

What are Drop Pipe Elevators and How Do They Work?

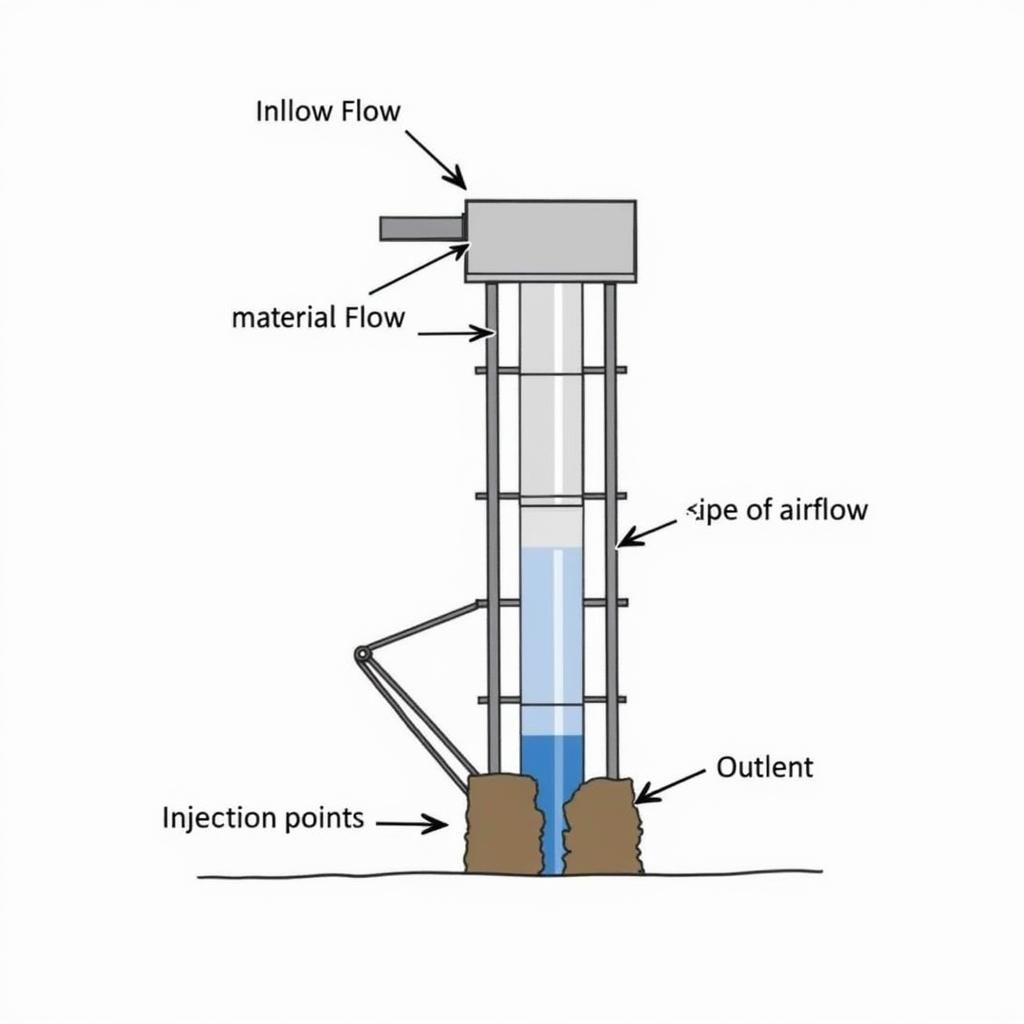

Drop pipe elevators utilize gravity and controlled airflow to transport materials downwards through a vertical pipe. Unlike traditional bucket elevators that lift materials, drop pipe systems facilitate a controlled descent. This makes them particularly suitable for applications where materials need to be transferred from a higher to a lower level. The process begins with feeding material into the top of the pipe. As the material falls through the pipe, air is introduced to regulate the flow and prevent clogging. This controlled descent minimizes material degradation and ensures a consistent discharge at the bottom.

Diagram of a drop pipe elevator system

Diagram of a drop pipe elevator system

Advantages of Using Drop Pipe Elevators

Drop pipe elevators offer several advantages over other material handling methods. They are known for their gentle handling, which minimizes damage to fragile materials. Their enclosed design prevents dust and spillage, contributing to a cleaner and safer work environment. Furthermore, drop pipe systems require less maintenance compared to mechanical elevators, reducing downtime and operational costs. They also boast a relatively simple design, which translates to easier installation and operation.

Key Applications of Drop Pipe Elevators

Drop pipe elevators find applications in a wide range of industries. They are commonly used in the agricultural sector for handling grains and feeds. In the food processing industry, they are employed for transporting delicate ingredients like flour and sugar. Other applications include handling plastic pellets in the plastics industry and moving powders in the chemical industry. Their versatility makes them a valuable asset in various industrial settings.

Drop pipe elevator operating in a grain handling facility

Drop pipe elevator operating in a grain handling facility

Designing and Implementing a Drop Pipe Elevator System

Several factors must be considered when designing and implementing a drop pipe elevator system. The pipe diameter, material, and airflow rate are crucial for efficient operation. The material properties, such as density and flow characteristics, also influence the design. Properly integrating the drop pipe elevator with other material handling equipment is essential for seamless material flow throughout the facility.

Maintaining and Troubleshooting Drop Pipe Elevators

Regular maintenance is vital for ensuring the long-term performance of drop pipe elevators. Inspecting the pipe for wear and tear, checking the airflow system, and cleaning the system regularly are crucial maintenance tasks. Troubleshooting common issues, such as blockages and airflow inconsistencies, can prevent major problems and minimize downtime.

Maintenance checklist for a drop pipe elevator

Maintenance checklist for a drop pipe elevator

Conclusion

Drop pipe elevators offer a reliable and efficient solution for vertically transporting bulk materials in various industrial settings. Their gentle handling, enclosed design, and low maintenance requirements make them a cost-effective choice. By carefully considering design parameters, integrating the system effectively, and implementing a regular maintenance schedule, businesses can maximize the benefits of drop pipe elevators and optimize their material handling processes. For further information and expert guidance on implementing drop pipe elevators, don’t hesitate to contact us.

FAQ

- What types of materials can be transported using drop pipe elevators?

- What are the main advantages of drop pipe elevators over bucket elevators?

- How does airflow control impact the performance of a drop pipe elevator?

- What are the key maintenance requirements for a drop pipe elevator system?

- How can I determine the appropriate pipe diameter for my application?

- What are some common troubleshooting tips for drop pipe elevator issues?

- How do I integrate a drop pipe elevator into my existing material handling system?

Common Scenarios and Questions:

- Scenario: Material flow is inconsistent. Possible Cause: Airflow issues or blockages.

- Scenario: Excessive material degradation. Possible Cause: Incorrect airflow rate or pipe material.

- Scenario: System downtime due to blockages. Possible Cause: Insufficient cleaning or material buildup.

Further Reading:

- Exploring Different Types of Material Handling Equipment

- Optimizing Material Flow in Industrial Facilities

When you need assistance, please contact Phone Number: 0963418788, Email: [email protected] or visit our address: 2M4H+PMH, Phường Nghĩa Thành, Gia Nghĩa, Đắk Nông, Việt Nam. We have a 24/7 customer service team.