Mastering the Cleveland Kettle: A Comprehensive Guide

October 29, 2024Cleveland Kettles are renowned for their durability and performance in industrial settings. Whether you’re a seasoned professional or new to these powerful pieces of equipment, understanding their features and operation is crucial for maximizing efficiency and safety. This guide will delve into everything you need to know about Cleveland kettles, from their various applications to maintenance best practices.

Understanding the Cleveland Kettle’s Power

Cleveland kettles are more than just large cooking pots. They are sophisticated pieces of machinery designed for specific industrial processes, offering precise temperature control and robust construction. This allows for consistent results and a long lifespan, making them a valuable asset in various industries. They are especially popular in food processing, pharmaceuticals, and chemical manufacturing, where precise heating and mixing are essential. Having a firm grasp of their capabilities is the first step towards utilizing their full potential.

Here’s a quick breakdown of why Cleveland kettles are preferred in industrial settings:

- Precise Temperature Control: Maintaining accurate temperatures is critical for many industrial processes. Cleveland kettles excel in this area, offering fine-tuned control over heating and cooling.

- Durable Construction: Built to withstand harsh industrial environments, these kettles are typically made from stainless steel or other robust materials, ensuring longevity and reliability.

- Versatile Applications: From cooking large batches of food to mixing chemicals, Cleveland kettles adapt to diverse needs, making them a versatile investment for various industries.

Key Features of a Cleveland Kettle

Understanding the key features of a Cleveland kettle is essential for selecting the right model for your specific needs. From the type of agitation to the heating method, each component plays a crucial role in the overall performance of the kettle. Let’s explore some of the most important features:

- Agitation System: Different models offer various agitation options, from simple paddles to complex mixing systems, allowing you to choose the best fit for your application.

- Heating Method: Whether it’s steam, electric, or direct fire, the heating method impacts the kettle’s efficiency and operating costs. Consider your energy sources and production requirements when making this decision.

- Material Construction: The material of the kettle directly affects its durability and resistance to corrosion. Stainless steel is a common choice due to its strength and hygiene properties.

- Control System: Modern Cleveland kettles often come equipped with sophisticated control systems that allow for precise temperature regulation and automated processes.

Maintaining Your Cleveland Kettle

Proper maintenance is crucial for extending the life of your Cleveland kettle and ensuring optimal performance. Regular cleaning and inspection can prevent costly repairs and downtime. Here are some key maintenance practices:

- Regular Cleaning: Clean the kettle thoroughly after each use to remove any residue and prevent buildup.

- Inspection of Seals and Gaskets: Regularly check the seals and gaskets for wear and tear. Replace them promptly to avoid leaks and maintain efficiency.

- Calibration of Controls: Ensure the control systems are calibrated correctly to maintain accurate temperature control and prevent product inconsistencies.

“Regular maintenance is not just about keeping your equipment clean,” says John Smith, Senior Engineer at Industrial Equipment Solutions, “it’s about ensuring consistent quality and preventing costly breakdowns. A well-maintained Cleveland kettle is a productive Cleveland kettle.”

Cleveland Kettle Maintenance Checklist

Cleveland Kettle Maintenance Checklist

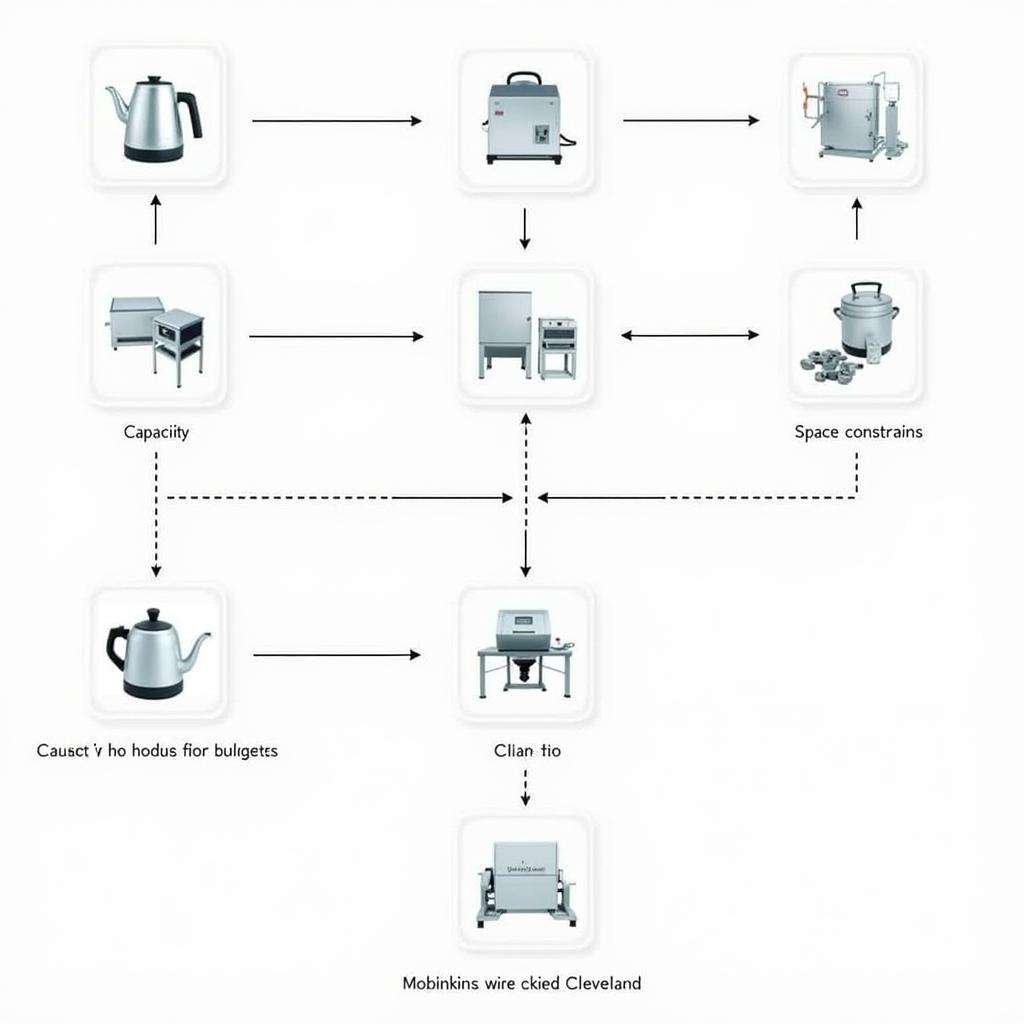

Choosing the Right Cleveland Kettle

Choosing the correct Cleveland kettle for your specific needs requires careful consideration of several factors. Understanding your production requirements, budget, and available space will help you make an informed decision.

- Capacity: Determine the required volume based on your production needs. Overestimating or underestimating capacity can lead to inefficiencies.

- Budget: Cleveland kettles come in a range of prices. Establish a budget early in the process to narrow down your options.

- Space Constraints: Consider the physical dimensions of the kettle and ensure it fits comfortably within your facility.

“Investing in the right Cleveland kettle is a significant decision,” advises Maria Garcia, Process Engineer at FoodTech Solutions. “Take the time to assess your needs and consult with experts to ensure you choose the best fit for your operation.”

Choosing the Right Cleveland Kettle

Choosing the Right Cleveland Kettle

Conclusion

Cleveland kettles are powerful tools in various industrial settings. Understanding their features, maintenance requirements, and selection process is essential for maximizing their potential and achieving optimal results. By following the guidelines in this guide, you can ensure your Cleveland kettle remains a valuable asset for years to come.

FAQ

- What are the primary uses of a Cleveland kettle? Cleveland kettles are primarily used in food processing, pharmaceuticals, and chemical manufacturing.

- How often should I clean my Cleveland kettle? Cleaning should be done after each use to prevent buildup and maintain hygiene.

- What materials are Cleveland kettles made of? They are typically constructed from stainless steel or other durable materials.

- What are the different heating options available? Cleveland kettles can be heated using steam, electricity, or direct fire.

- How do I choose the right size Cleveland kettle? Consider your production volume and available space when selecting the appropriate size.

- Where can I find replacement parts for my Cleveland kettle? cleveland kettle parts

- What are the key maintenance tasks for a Cleveland Kettle? Regular cleaning, inspection of seals, and calibration of controls are essential.

For further assistance, please contact us at Phone Number: 0963418788, Email: [email protected] Or visit us at: 2M4H+PMH, Phường Nghĩa Thành, Gia Nghĩa, Đắk Nông, Việt Nam. We have a 24/7 customer support team.