Aluminum C Slide Track Channel: A Comprehensive Guide

November 8, 2024Aluminum C Slide Track Channels are essential components in various applications, offering a robust and versatile solution for linear motion systems. They provide a smooth, low-friction pathway for sliding components, ensuring precise and reliable movement. From industrial automation to DIY projects, understanding the nuances of these channels can greatly enhance your design and build process.

Understanding Aluminum C Slide Track Channels

What exactly are aluminum C slide track channels? These channels, often referred to as C-channels due to their distinctive shape, are extruded aluminum profiles designed to guide and support moving parts. Their robust construction and precise dimensions make them ideal for applications requiring accurate linear motion. The “C” shape provides inherent strength and stability, allowing them to handle significant loads and resist bending or twisting. The smooth inner surface minimizes friction, ensuring efficient and quiet operation.

The versatility of aluminum C slide track channels stems from their adaptability to various configurations. They can be mounted horizontally, vertically, or even inverted, depending on the specific application. This flexibility makes them suitable for a wide range of projects, from simple drawer slides to complex robotic systems.

Key Benefits of Using Aluminum C Slide Track Channels

Why choose aluminum C slide track channels over other linear motion solutions? Several key advantages make them a preferred choice for many applications:

- Durability: Aluminum’s inherent resistance to corrosion and wear ensures a long lifespan, even in demanding environments.

- Lightweight: Compared to steel alternatives, aluminum C-channels are significantly lighter, reducing overall system weight and improving efficiency.

- Easy Machining: Aluminum is readily machinable, allowing for customization and adaptation to specific project requirements.

- Cost-Effective: Aluminum offers a balance of performance and affordability, making it an attractive option for various budgets.

These benefits contribute to the widespread use of aluminum C slide track channels across diverse industries, including automation, robotics, material handling, and even furniture design.

Choosing the Right Aluminum C Slide Track Channel

Selecting the appropriate aluminum C slide track channel requires careful consideration of several factors:

- Load Capacity: Determine the maximum weight the channel will need to support to ensure structural integrity.

- Size and Dimensions: Choose a channel size that accommodates the moving components and fits within the overall system design.

- Mounting Options: Consider how the channel will be mounted and select appropriate hardware and accessories.

- Material Finish: Different finishes, such as anodized or powder-coated, offer varying levels of protection and aesthetics.

Applications of Aluminum C Slide Track Channels

Where are aluminum C slide track channels commonly used? Their versatility makes them suitable for a wide range of applications:

- Robotics and Automation: Providing precise linear motion for robotic arms and automated systems.

- Material Handling: Facilitating the movement of goods and materials in warehouses and factories.

- CNC Machines: Guiding cutting tools and workpieces with accuracy and stability.

- DIY Projects: Enabling smooth and reliable movement in custom-built furniture, drawers, and other applications.

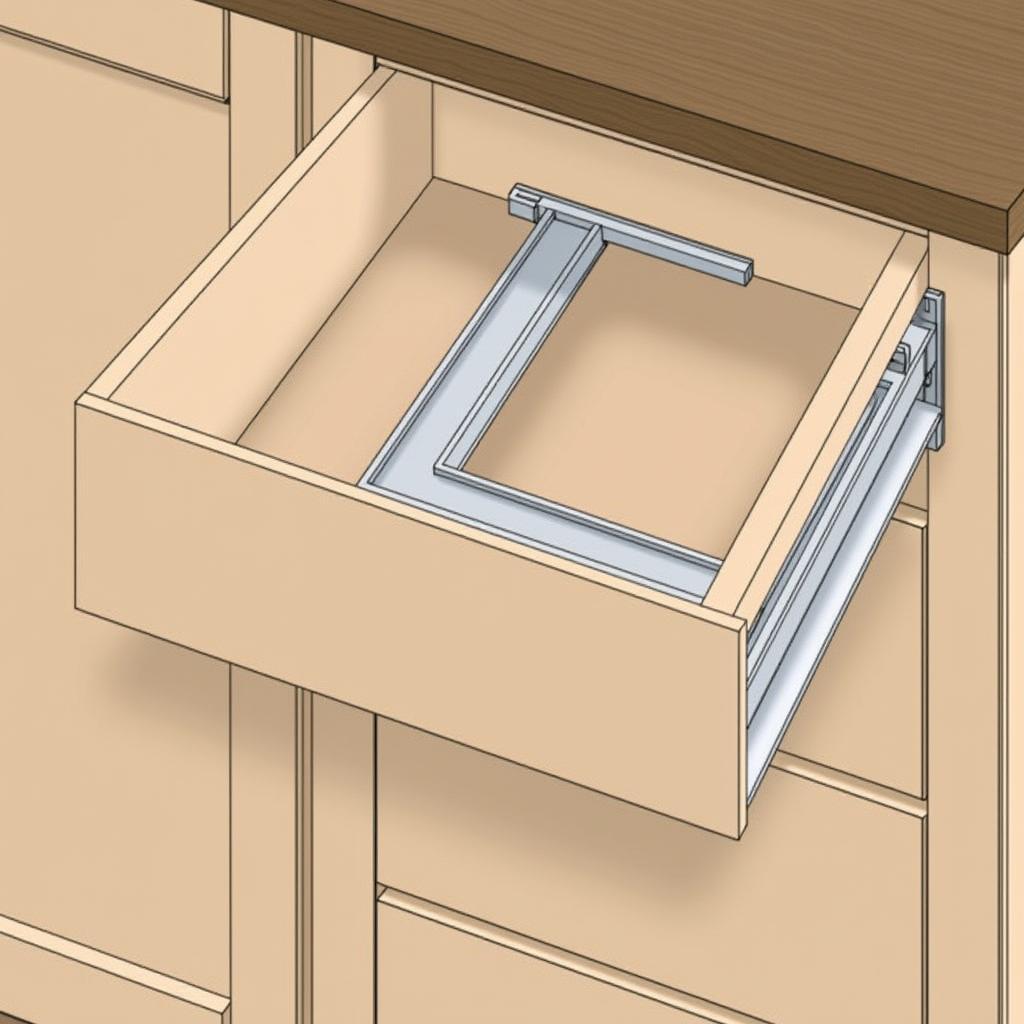

DIY Project Utilizing Aluminum C Channel for Drawer Slides

DIY Project Utilizing Aluminum C Channel for Drawer Slides

Conclusion

Aluminum C slide track channels offer a robust, versatile, and cost-effective solution for linear motion applications. Their durability, lightweight nature, and ease of machining make them an ideal choice for a wide range of projects, from industrial automation to DIY creations. By understanding the key considerations for selecting and implementing these channels, you can optimize your designs and achieve precise, reliable, and efficient linear motion.

FAQ

- What are the standard sizes for aluminum C slide track channels?

- How do I calculate the load capacity of an aluminum C channel?

- What types of lubricants are recommended for use with aluminum C slide track channels?

- What are the different mounting options available for these channels?

- Where can I purchase aluminum C slide track channels?

- What are the advantages of using anodized aluminum C channels?

- Are there any specialized C channels for high-speed applications?

Need further assistance? Contact us at Phone: 0963418788, Email: [email protected] Or visit our address: 2M4H+PMH, Phường Nghĩa Thành, Gia Nghĩa, Đắk Nông, Việt Nam. We have a 24/7 customer support team.