Understanding KC Castings: A Comprehensive Guide

October 17, 2024Kc Castings are an integral part of various industries, playing a crucial role in manufacturing a wide range of products. From automotive components to aerospace parts, the versatility and durability of KC castings make them indispensable in modern manufacturing.

KC Castings Applications

KC Castings Applications

What are KC Castings?

KC castings refer to components created through the casting process using a specific alloy known for its superior properties. This alloy typically comprises a precise blend of metals, with each element contributing to the casting’s overall strength, corrosion resistance, and machinability. The “KC” designation often represents a specific alloy composition or a manufacturer’s proprietary blend.

Advantages of Choosing KC Castings

Advantages of KC Castings

Advantages of KC Castings

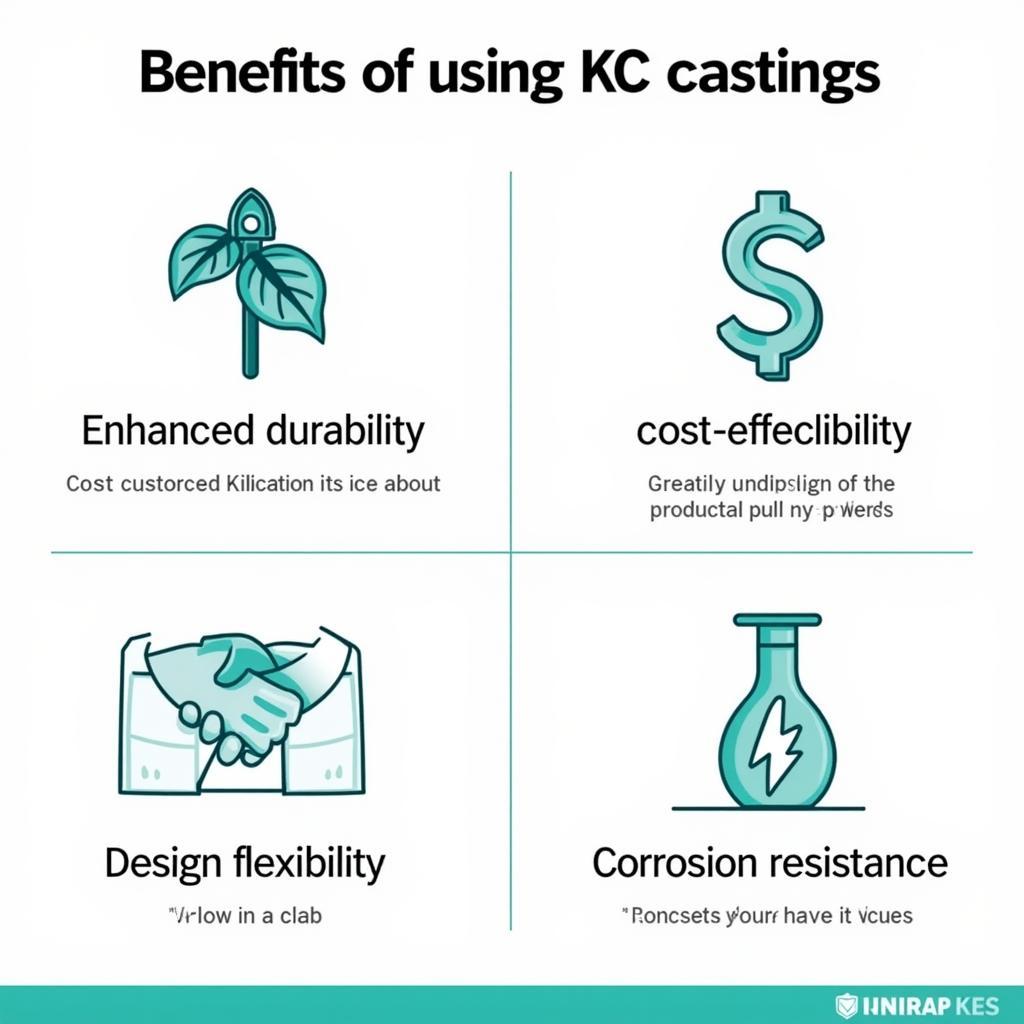

Several factors contribute to the popularity of KC castings across industries:

- Durability: KC castings are known for their exceptional strength and resistance to wear and tear, making them ideal for demanding applications.

- Cost-Effectiveness: The casting process offers a cost-effective solution, especially for high-volume production runs.

- Design Flexibility: KC castings allow for intricate designs and complex geometries, providing engineers with greater design freedom.

- Corrosion Resistance: The unique alloy composition of KC castings provides excellent resistance to corrosion, extending the lifespan of components.

Applications of KC Castings

The versatility of KC castings is evident in their wide range of applications:

- Automotive Industry: Engine blocks, cylinder heads, transmission cases

- Aerospace Industry: Turbine blades, structural components

- Industrial Machinery: Gears, pump housings, valve bodies

The KC Casting Process: A Closer Look

The production of KC castings involves a carefully controlled process:

- Mold Creation: A mold is created using a pattern of the desired component.

- Metal Melting and Pouring: The KC alloy is melted to a specific temperature and poured into the mold cavity.

- Solidification and Cooling: The molten metal solidifies within the mold, taking the shape of the component.

- Removal and Cleaning: The casting is removed from the mold, and any excess material is trimmed.

- Inspection and Finishing: Each casting undergoes rigorous inspection to ensure quality and dimensional accuracy.

Choosing the Right KC Casting Supplier

Selecting a reputable KC casting supplier is essential to ensure the quality and reliability of your components.

“When choosing a supplier, consider their experience, quality control measures, and ability to meet your specific requirements,” advises [Expert Name], a leading materials engineer. “A reliable supplier will work closely with you throughout the process, from design to delivery.”

KC Castings Quality Control

KC Castings Quality Control

Conclusion

KC castings have become essential components in many industries due to their exceptional properties and cost-effectiveness. Understanding the advantages, applications, and manufacturing process of KC castings can help businesses make informed decisions when selecting materials for their products. By partnering with a reliable KC casting supplier, companies can benefit from high-quality components that meet their exact specifications.