Understanding the Precision of Metal Misting Systems

October 11, 2024Metal Misting Systems have become increasingly popular for a variety of applications, from coating delicate electronics to creating durable automotive parts. But what exactly is a metal misting system and how does it achieve such precise results? This article will delve into the intricacies of this technology, exploring its principles, advantages, and diverse applications.

What Makes Metal Misting Systems Unique?

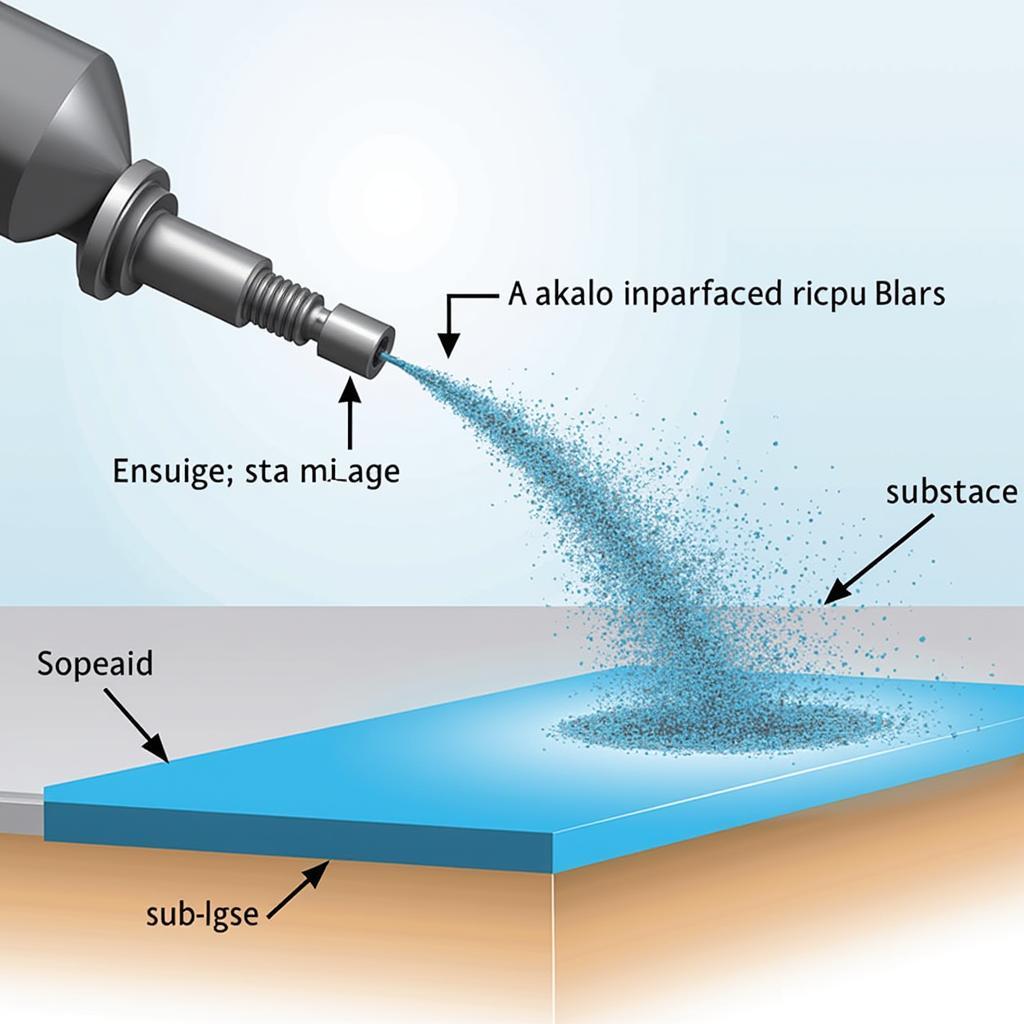

Unlike traditional thermal spraying techniques that rely on high heat, metal misting systems utilize a process called cold spray. This method propels fine metal particles at supersonic speeds using a compressed gas, typically nitrogen or helium. As these particles impact the substrate, they undergo plastic deformation and bond mechanically, forming a strong, dense coating.

Cold Spray Process Illustration

Cold Spray Process Illustration

The absence of heat in the coating process offers several key advantages. First, it eliminates the risk of heat-affected zones, which can weaken the substrate or alter its properties. This makes metal misting ideal for heat-sensitive materials and applications requiring high precision. Secondly, the cold spray process generates minimal waste, making it an environmentally friendly solution.

Applications Across Industries

The versatility of metal misting systems has led to their widespread adoption in various industries.

1. Aerospace: Enhancing Component Durability

In the demanding environment of aerospace, component reliability is paramount. Metal misting is used to apply protective coatings on turbine blades, engine components, and other critical parts, enhancing their resistance to wear, corrosion, and extreme temperatures.

2. Automotive: Improving Efficiency and Performance

Metal misting plays a vital role in enhancing the performance and efficiency of automotive components. From coating piston rings to creating wear-resistant surfaces on gears, this technology helps reduce friction, improve fuel efficiency, and extend component lifespan.

Automotive Gear Coated with Metal Misting

Automotive Gear Coated with Metal Misting

3. Electronics: Protecting Delicate Components

The electronics industry demands precision and minimal heat impact. Metal misting excels in this field, enabling the application of thin, conductive coatings on printed circuit boards, semiconductors, and other electronic components, ensuring optimal performance and protection.

Factors Influencing Coating Quality

Achieving high-quality coatings with a metal misting system depends on various factors:

- Particle Size and Morphology: The size and shape of the metal particles significantly influence coating properties like porosity and adhesion.

- Gas Pressure and Temperature: Precise control over gas pressure and temperature is crucial for achieving the desired particle velocity and deposition efficiency.

- Spray Distance and Angle: The distance and angle between the spray nozzle and the substrate affect the particle impact energy and coating uniformity.

Future Trends in Metal Misting

As technology advances, metal misting systems are continuously evolving. Ongoing research focuses on developing new coating materials, optimizing process parameters, and integrating artificial intelligence for process control and quality assurance.

Metal Misting System with Robotic Arm

Metal Misting System with Robotic Arm

Conclusion

Metal misting systems have revolutionized surface coating technology, offering unmatched precision, versatility, and environmental friendliness. Their ability to create durable, high-performance coatings on various materials makes them indispensable across industries, from aerospace to electronics. As research and development continue to push the boundaries of this technology, we can expect even more innovative applications and further advancements in coating quality and efficiency.

For expert advice on integrating a metal misting system into your operations, feel free to reach out. Contact us at Phone Number: 0963418788, Email: [email protected] Or visit us at: 2M4H+PMH, Nghĩa Thành Ward, Gia Nghĩa City, Đắk Nông Province, Vietnam. Our dedicated team is available 24/7 to answer your questions.