Understanding Depth Limiting Rings

November 14, 2024Depth Limiting Rings are essential tools for controlling the depth of penetration in various applications, from drilling and construction to underwater exploration and even medical procedures. They provide a physical barrier that restricts movement beyond a predetermined point, ensuring accuracy, safety, and efficiency.

What are Depth Limiting Rings and Their Applications?

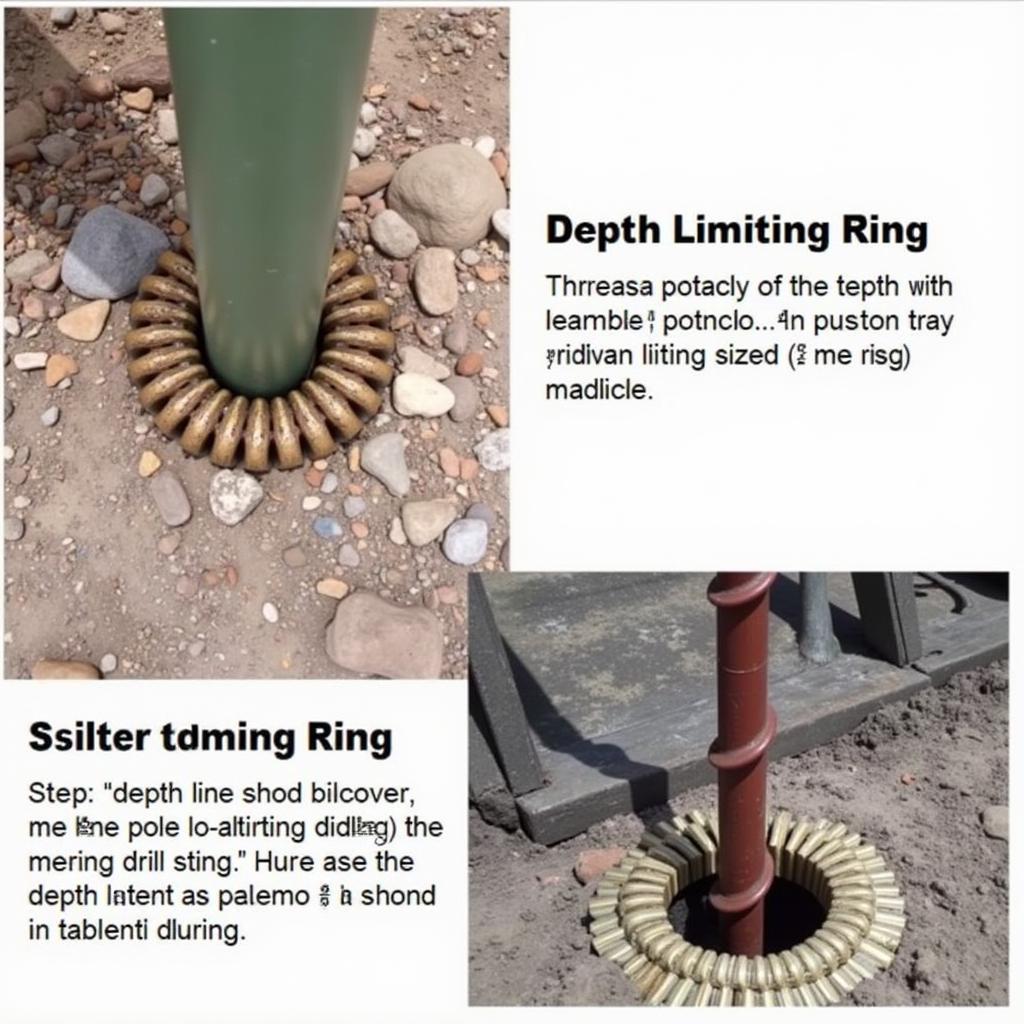

Depth limiting rings, also known as stop collars or depth stops, are precisely engineered rings designed to limit the insertion depth of an object into a borehole, pipe, or other cavity. These rings are typically made from durable materials like steel, stainless steel, or specialized plastics, depending on the specific application and environmental conditions. They play a crucial role in maintaining control and precision in numerous fields.

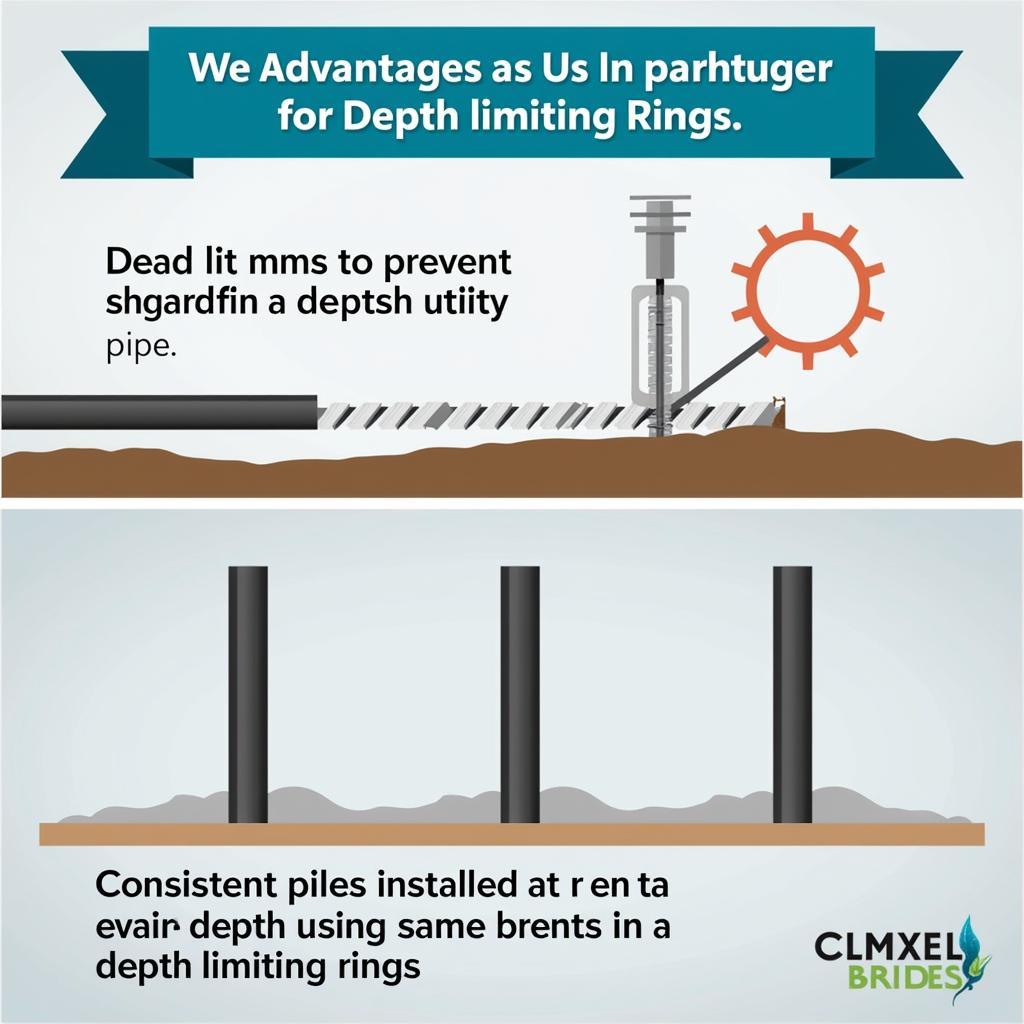

In construction, depth limiting rings ensure that piles, anchors, and other structural elements are installed at the correct depth, guaranteeing stability and structural integrity. In drilling operations, these rings prevent drill bits from penetrating too far, protecting underground utilities or sensitive geological formations. Underwater, they are used on remotely operated vehicles (ROVs) and other equipment to control the depth of exploration or sampling. Even in medical fields, depth limiting rings find applications in procedures requiring precise insertion depths, such as catheter placement.

Depth Limiting Rings in Drilling and Construction

Depth Limiting Rings in Drilling and Construction

Different Types of Depth Limiting Rings

Several types of depth limiting rings cater to various needs and applications. Fixed depth limiting rings are permanently attached to the object, offering a simple and reliable solution for applications with a constant depth requirement. Adjustable depth limiting rings, on the other hand, allow for variable depth control, offering flexibility in situations where the required depth may change. These adjustable rings can be secured using screws, clamps, or other mechanisms. Furthermore, specialized depth limiting rings are designed for specific applications, such as those used in the oil and gas industry, which often incorporate features like pressure resistance and corrosion protection.

Choosing the Right Depth Limiting Ring

Selecting the correct depth limiting ring depends on several factors, including the application, the required depth, the diameter of the object being inserted, and the environmental conditions. For instance, a fixed depth limiting ring might be suitable for a simple anchoring application, while an adjustable ring would be more appropriate for a drilling operation where the target depth may vary. Furthermore, the material of the ring should be chosen based on the surrounding environment. For example, stainless steel rings are preferable in corrosive environments like marine applications.

Types of Depth Limiting Rings: Fixed and Adjustable

Types of Depth Limiting Rings: Fixed and Adjustable

Advantages of Using Depth Limiting Rings

Depth limiting rings offer several significant advantages, contributing to increased efficiency, improved safety, and cost savings. By precisely controlling depth, they minimize the risk of errors and rework, reducing material waste and labor costs. They also enhance safety by preventing over-penetration, which can damage equipment, infrastructure, or even cause injury. Furthermore, depth limiting rings help ensure consistency and accuracy, leading to higher quality results. For example, in medical procedures, precise depth control is crucial for patient safety and treatment efficacy.

“Using depth limiting rings has significantly improved the precision and efficiency of our drilling operations,” says Dr. Emily Carter, a renowned geologist with over 20 years of experience in the field. “They have become an indispensable tool for ensuring accuracy and safety in our projects.”

Depth Limiting Rings: Frequently Asked Questions

1. What materials are depth limiting rings made of?

Depth limiting rings are typically made from steel, stainless steel, or specialized plastics.

2. What are the main types of depth limiting rings?

The two main types are fixed and adjustable depth limiting rings.

3. How do I choose the right depth limiting ring?

Consider the application, required depth, object diameter, and environmental conditions.

4. What are the advantages of using depth limiting rings?

They enhance accuracy, improve safety, increase efficiency, and reduce costs.

5. Where can I purchase depth limiting rings?

Depth limiting rings can be purchased from specialized suppliers or online retailers.

6. What are some common applications of depth limiting rings?

They are used in construction, drilling, underwater exploration, and medical procedures.

7. How do depth limiting rings contribute to safety?

They prevent over-penetration, which can damage equipment, infrastructure, or cause injury.

Depth Limiting Ring Advantages: Safety and Efficiency

Depth Limiting Ring Advantages: Safety and Efficiency

Conclusion

Depth limiting rings are invaluable tools for achieving precision and control in various applications. Their ability to restrict depth of penetration ensures accuracy, enhances safety, and improves overall efficiency. By carefully considering the factors discussed in this article, you can choose the right depth limiting ring for your specific needs and maximize the benefits they offer. Remember, selecting the appropriate depth limiting ring is crucial for successful project completion and operational safety.

“Investing in high-quality depth limiting rings is a wise decision for any operation requiring precise depth control,” adds Michael Rodriguez, a senior engineer with extensive experience in construction and infrastructure projects. “The benefits in terms of safety, efficiency, and cost savings are undeniable.”

Need further assistance? Please contact us at Phone Number: 0963418788, Email: [email protected] Or visit us at: 2M4H+PMH, Phường Nghĩa Thành, Gia Nghĩa, Đắk Nông, Việt Nam. We have a 24/7 customer service team.