Choosing the Right Glass Cutting Gloves

November 10, 2024Glass cutting, whether it’s for a DIY project or professional work, requires precision and, most importantly, safety. Protecting your hands is paramount, and that’s where Glass Cutting Gloves come into play. These specialized gloves offer a crucial barrier against sharp edges and potential injuries.

When handling glass, you’re dealing with a material that can be surprisingly dangerous. Even seemingly small shards can cause significant cuts. That’s why investing in a good pair of glass cutting gloves is non-negotiable. They provide the necessary protection to allow you to work confidently and efficiently. But with so many options on the market, how do you choose the right pair? This guide will explore everything you need to know about glass cutting gloves, helping you make an informed decision and keep your hands safe.

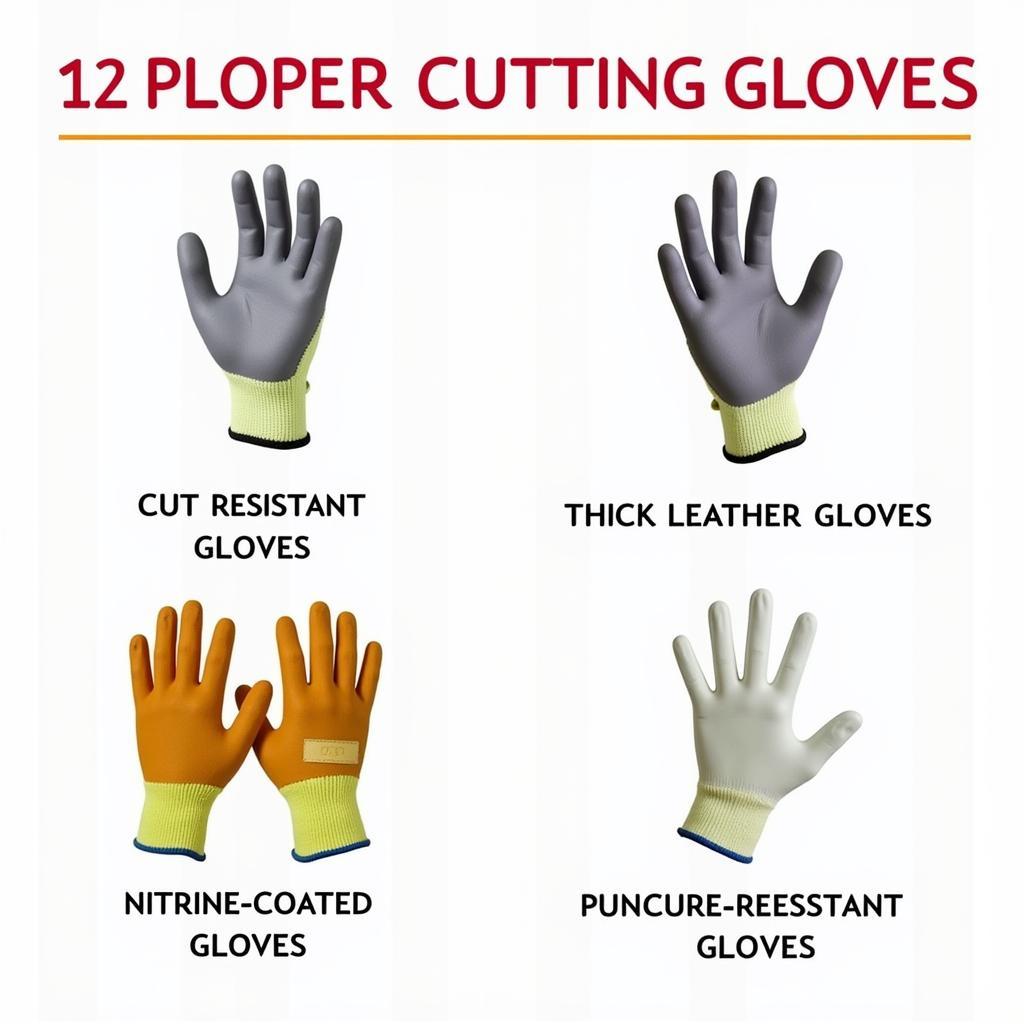

Different Types of Glass Cutting Gloves

There are several types of glass cutting gloves available, each designed for specific needs and levels of protection. Understanding the differences can help you choose the best gloves for your situation.

-

Cut-Resistant Gloves: These gloves are typically made from materials like Kevlar, Dyneema, or high-performance polyethylene (HPPE). They offer excellent protection against cuts and abrasions, making them ideal for handling sharp glass edges. They come in various cut levels, with higher levels offering greater protection.

-

Leather Gloves: While not specifically designed for glass cutting, thick leather gloves can provide some level of protection against minor cuts and scrapes. However, they are not as cut-resistant as specialized gloves and may not be suitable for handling very sharp or thin glass.

-

Coated Gloves: Some gloves are coated with materials like nitrile or polyurethane to enhance grip and dexterity. These coatings can also provide an additional layer of protection against cuts and punctures. They’re a great option for tasks requiring a delicate touch.

-

Puncture-Resistant Gloves: Designed to protect against sharp objects penetrating the glove, these gloves are particularly useful when working with broken glass or sharp metal.

Different Types of Glass Cutting Gloves

Different Types of Glass Cutting Gloves

Key Features to Consider When Buying Glass Cutting Gloves

Selecting the right glass cutting gloves involves more than just choosing a material. Several key features contribute to their overall effectiveness and comfort.

-

Cut Resistance Level: Look for gloves with an ANSI/ISEA cut level rating. Higher numbers indicate greater protection. For glass cutting, a level A4 or higher is recommended.

-

Dexterity: Maintaining dexterity while wearing gloves is crucial for precise glass handling. Choose gloves that fit snugly and allow for a good range of motion in your fingers.

-

Comfort: Gloves should be comfortable to wear for extended periods. Consider features like breathability and moisture-wicking capabilities to prevent sweating and discomfort.

-

Durability: Invest in gloves that are durable and can withstand repeated use. Look for reinforced stitching and high-quality materials.

-

Grip: A good grip is essential for handling glass safely. Look for gloves with textured palms or coated fingertips.

How to Properly Use and Care for Your Glass Cutting Gloves

Maximizing the lifespan and effectiveness of your glass cutting gloves requires proper use and care.

-

Inspection: Before each use, inspect your gloves for any signs of damage, such as tears or cuts. Replace damaged gloves immediately.

-

Proper Fit: Ensure the gloves fit snugly but not too tightly. Ill-fitting gloves can reduce dexterity and increase the risk of injury.

-

Cleaning: Follow the manufacturer’s instructions for cleaning your gloves. Some gloves can be washed, while others require specialized cleaning methods.

-

Storage: Store your gloves in a clean, dry place away from direct sunlight and heat.

What are the Benefits of Wearing Glass Cutting Gloves?

Wearing glass cutting gloves provides numerous benefits, primarily centered around safety and enhanced performance. They act as a vital barrier between your skin and the sharp edges of glass, preventing cuts, lacerations, and abrasions. This protection allows for greater confidence and control when handling glass, leading to improved precision and efficiency. Furthermore, the right gloves can enhance your grip, reducing the risk of dropping or breaking glass.

Why are Cut-Resistant Gloves Important for Glass Handling?

Specifically designed to resist cuts and lacerations, cut-resistant gloves are particularly crucial for handling glass. The sharp edges of glass pose a significant risk of injury, and these gloves provide a much-needed layer of protection. This specialized protection allows for safer and more efficient glass handling, minimizing the risk of accidents.

In conclusion, investing in a quality pair of glass cutting gloves is essential for anyone working with glass. They provide crucial protection against cuts and injuries, allowing you to work confidently and efficiently. By understanding the different types of gloves available and considering the key features, you can choose the right pair to meet your specific needs and keep your hands safe while working with glass cutting gloves.

FAQ

- What is the best cut level for glass cutting gloves? A level A4 or higher is recommended for handling glass.

- Can I wash my glass cutting gloves? Check the manufacturer’s instructions as cleaning methods vary.

- What are glass cutting gloves made of? Common materials include Kevlar, Dyneema, and HPPE.

- How often should I replace my glass cutting gloves? Replace them immediately if damaged, or as recommended by the manufacturer.

- Are leather gloves suitable for glass cutting? While they offer some protection, they are not as cut-resistant as specialized gloves.

- What features should I look for in glass cutting gloves? Consider cut resistance, dexterity, comfort, durability, and grip.

- Why is grip important for glass cutting gloves? A good grip helps prevent accidental slips and breakage.

When you need assistance, please contact us by phone at 0963418788, email at [email protected] or visit us at 2M4H+PMH, Phường Nghĩa Thành, Gia Nghĩa, Đắk Nông, Việt Nam. We have a 24/7 customer service team.