Understanding Henry and Henry Filling

November 6, 2024Henry And Henry Filling is a crucial aspect of various industries, from construction to food processing. This article will delve into the intricacies of this process, exploring its applications, benefits, and potential challenges. We’ll examine different types of Henry and Henry filling, discuss the equipment involved, and offer insights into optimizing the process for efficiency and effectiveness.

What is Henry and Henry Filling?

While the term “Henry and Henry filling” doesn’t correspond to a recognized industrial process, it likely stems from a misunderstanding or a specific, niche application. This article will therefore address filling processes in general, assuming “Henry and Henry” might refer to a specific brand or company. We’ll cover common filling methods applicable across various industries, hoping to provide valuable information relevant to the user’s search intent.

Different Types of Filling Processes

Several filling methods cater to diverse products and industries. These include:

- Gravity Filling: Utilizing gravity to dispense liquids into containers. This method is suitable for low-viscosity products.

- Pressure Filling: Employing pressure to transfer liquids into containers, ideal for higher-viscosity products or those containing particulates.

- Piston Filling: Using a piston mechanism to accurately dispense a predetermined volume of product. This method is versatile and suitable for various viscosities.

- Auger Filling: Utilizing an auger to dispense dry products like powders or granules into containers.

Understanding the characteristics of the product being filled is crucial for selecting the appropriate method. Factors such as viscosity, density, and temperature can all influence the filling process.

Different Types of Filling Machines

Different Types of Filling Machines

Optimizing the Filling Process

Optimizing the filling process is crucial for maximizing efficiency and minimizing waste. Key factors to consider include:

- Accuracy: Ensuring accurate fill volumes is essential for product consistency and consumer satisfaction.

- Speed: Optimizing the filling speed can significantly impact production output.

- Hygiene: Maintaining hygienic conditions throughout the filling process is crucial for product safety and quality.

- Maintenance: Regular maintenance of filling equipment can prevent breakdowns and ensure consistent performance.

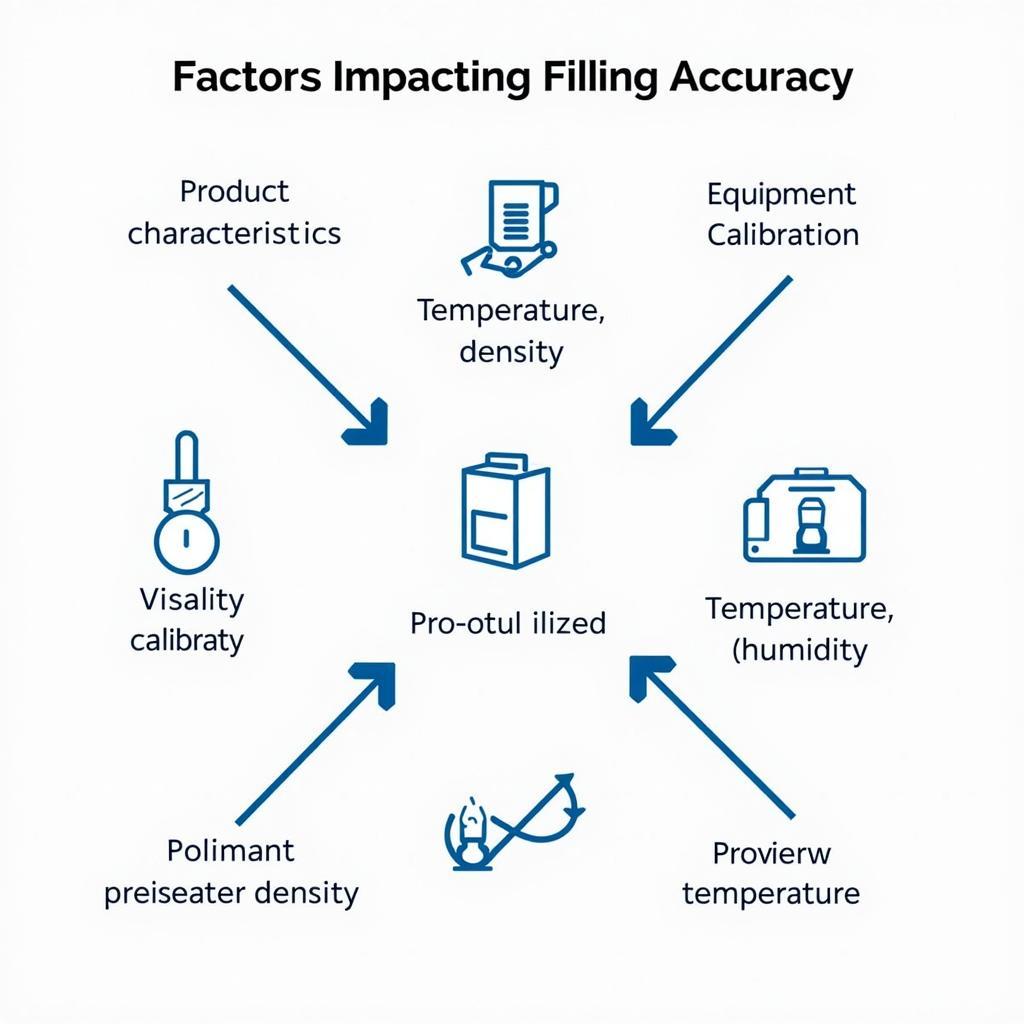

Factors Affecting Filling Accuracy

Several factors can influence the accuracy of the filling process:

- Product Characteristics: Viscosity, temperature, and density can affect the flow rate and fill volume.

- Equipment Calibration: Regular calibration of filling equipment is crucial for maintaining accuracy.

- Environmental Factors: Temperature and humidity can also influence the filling process.

Factors Affecting Filling Accuracy in Production

Factors Affecting Filling Accuracy in Production

Choosing the Right Filling Equipment

Selecting the appropriate filling equipment is crucial for ensuring efficient and accurate filling. Consider the following factors:

- Product Type: The type of product being filled will dictate the appropriate filling method and equipment.

- Production Volume: The required production volume will influence the size and capacity of the filling equipment.

- Budget: Filling equipment can vary significantly in price, so it’s essential to consider budget constraints.

Maintaining Filling Equipment

Regular maintenance of filling equipment is crucial for preventing breakdowns and ensuring consistent performance. This includes:

- Cleaning: Regularly cleaning the equipment helps prevent contamination and maintain hygiene.

- Lubrication: Proper lubrication ensures smooth operation and reduces wear and tear.

- Inspection: Regular inspection can identify potential problems before they escalate into major breakdowns.

Maintaining Industrial Filling Equipment for Optimal Performance

Maintaining Industrial Filling Equipment for Optimal Performance

Conclusion

Understanding the nuances of filling processes, regardless of the specific “Henry and Henry” reference, is crucial for various industries. By carefully considering product characteristics, optimizing the filling process, and selecting the right equipment, businesses can enhance efficiency, reduce waste, and ensure product quality. Remember, efficient filling is a cornerstone of successful production.

FAQ

- What are the different types of filling methods?

- How can I optimize the filling process for my product?

- What factors should I consider when choosing filling equipment?

- How important is regular maintenance of filling equipment?

- What are the common challenges in filling processes?

- How can I improve the accuracy of my filling process?

- What are the latest advancements in filling technology?

Need help with your filling process? Contact us: Phone: 0963418788, Email: fandejong@gmail.com or visit us at: 2M4H+PMH, Phường Nghĩa Thành, Gia Nghĩa, Đắk Nông, Việt Nam. We have a 24/7 customer support team.