Thomas & Betts Zip Ties: The Ultimate Guide to Secure Fastening

October 30, 2024Choosing the Right Thomas & Betts Zip Ties for Your Needs

Selecting the appropriate zip tie can be daunting given the variety available. Factors to consider include tensile strength, material, and environmental conditions. For lighter applications like bundling wires in your home office, standard nylon zip ties are usually sufficient. However, for outdoor use or applications requiring higher strength, UV-resistant or stainless steel ties from Thomas & Betts are a better choice. Using the correct tie ensures a secure and long-lasting hold, preventing costly repairs or replacements down the line.

Understanding Zip Tie Tensile Strength

Tensile strength is a key factor in choosing the right zip tie. It refers to the maximum force a tie can withstand before breaking. Thomas & Betts offers a range of zip ties with varying tensile strengths to suit different needs. From lightweight ties for basic cable management to heavy-duty ties capable of securing larger objects, understanding tensile strength is critical for selecting the correct tie for the job. Overlooking this aspect can lead to failures and potential hazards, especially in demanding environments.

For example, imagine securing a heavy object with a low tensile strength tie. The tie could break under the strain, causing the object to fall and potentially causing damage or injury.

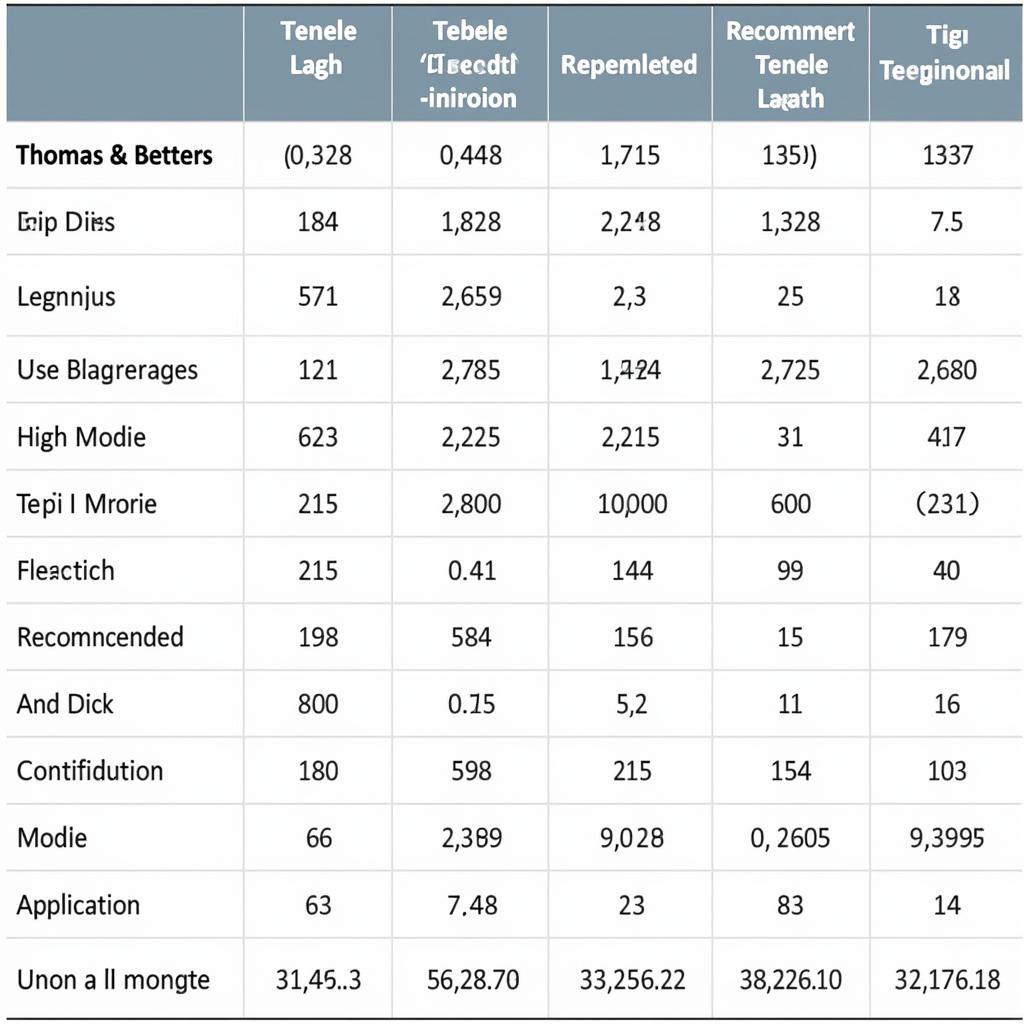

Thomas & Betts Zip Ties Tensile Strength Comparison Table

Thomas & Betts Zip Ties Tensile Strength Comparison Table

Material Matters: Selecting the Right Zip Tie Material

Thomas & Betts zip ties are available in various materials, each with its own set of properties and advantages. Nylon 6/6 is the most common material due to its excellent balance of strength, flexibility, and cost-effectiveness. For applications exposed to sunlight, UV-resistant nylon is crucial to prevent degradation and maintain long-term performance. In corrosive environments or applications requiring extreme durability, stainless steel ties offer unparalleled resistance.

Choosing the correct material ensures the longevity and effectiveness of the tie, minimizing the risk of failure and the need for frequent replacements.

Considering Environmental Factors

Environmental conditions play a significant role in zip tie selection. Exposure to UV radiation, extreme temperatures, or chemicals can impact the performance and lifespan of the tie. Thomas & Betts offers specialized ties designed to withstand harsh environments. For outdoor use, UV-resistant ties are essential to prevent degradation from sunlight. In chemically aggressive environments, using ties made from resistant materials like stainless steel is crucial to ensure long-term reliability.

Thomas & Betts Zip Tie Applications

Thomas & Betts zip ties are incredibly versatile and find applications in numerous industries and everyday scenarios. From bundling cables in data centers and securing wiring harnesses in automotive applications to organizing hoses in gardens and even crafting projects, these ties offer a simple yet effective fastening solution. Their versatility and reliability make them an indispensable tool for professionals and DIY enthusiasts alike.

Why Choose Thomas & Betts?

Thomas & Betts has a long-standing reputation for producing high-quality electrical components and fastening solutions. Their zip ties are known for their durability, reliability, and consistent performance. This commitment to quality ensures that users can rely on Thomas & Betts zip ties for even the most demanding applications.

Tips for Using Thomas & Betts Zip Ties

- Don’t overtighten: Overtightening can damage the tie and the bundled items.

- Trim the excess tail: After tightening, trim the excess tail flush with the lock to prevent snagging.

- Use the correct tool: Using the appropriate tensioning tool ensures consistent and secure fastening.

Proper Installation of Thomas & Betts Zip Ties with a Tensioning Tool

Proper Installation of Thomas & Betts Zip Ties with a Tensioning Tool

Conclusion

Thomas & Betts zip ties offer a reliable and versatile solution for a wide range of fastening needs. By understanding the different types, materials, and tensile strengths available, you can select the perfect tie for your specific application. Choosing Thomas & Betts ensures quality, durability, and long-lasting performance for all your fastening projects.

FAQ

- What is the difference between standard and UV-resistant zip ties? UV-resistant ties are formulated to withstand prolonged exposure to sunlight, preventing degradation and maintaining strength.

- What is the tensile strength of a zip tie? Tensile strength refers to the maximum force a tie can withstand before breaking.

- Where can I buy Thomas & Betts zip ties? They are available at most hardware stores and online retailers.

- How do I remove a zip tie? Use a zip tie cutter or a sharp knife to carefully cut the tie.

- Can I reuse a zip tie? No, once a zip tie is tightened and locked, it cannot be reused.

- What are some common uses for zip ties? Cable management, bundling wires, securing hoses, gardening, and crafting.

- What are the different sizes of Thomas & Betts zip ties available? They come in a wide range of lengths and widths to accommodate different applications.

Common Scenarios

- Securing cables in a data center: Use high tensile strength, flame-retardant zip ties.

- Bundling wires in a car: Choose abrasion-resistant and temperature-stable ties.

- Organizing garden hoses: Standard nylon zip ties are usually sufficient.

Further Reading

- Explore Thomas & Betts’ official website for detailed product specifications.

- Research different types of zip tie materials and their properties.

For further assistance, please contact us at Phone Number: 0963418788, Email: [email protected] or visit us at 2M4H+PMH, Phường Nghĩa Thành, Gia Nghĩa, Đắk Nông, Việt Nam. We have a 24/7 customer support team.