Understanding 1 2 ss Bolts

December 5, 2024As a midfielder, I understand the importance of precision and strength, much like the importance of choosing the right 1 2 Ss Bolts for a specific job. Whether you’re working on a car, building a piece of furniture, or tackling a DIY project, understanding the different types of bolts available is crucial for a successful and safe outcome. This article aims to delve into the world of 1 2 ss bolts, exploring their various types, applications, and best practices for selection and installation. Let’s kick things off.

Different Types of 1 2 ss Bolts and Their Uses

1 2 ss bolts, also known as 1/2 inch stainless steel bolts, are popular for their corrosion resistance and strength. This makes them ideal for a variety of applications, from marine environments to construction projects. Let’s examine some common types:

- Hex Head Bolts: These are probably the most recognizable type, featuring a hexagonal head for easy tightening with a wrench or socket. They’re versatile and used in countless applications.

- Carriage Bolts: Designed for use with wood, carriage bolts have a square section underneath the rounded head that prevents the bolt from turning as the nut is tightened. Think of projects like building a deck or concession window support bar.

- Eye Bolts: These bolts have a loop at the head, making them perfect for lifting or securing objects.

- Socket Head Cap Screws: Often used in machinery and automotive applications, these bolts have a cylindrical head with an internal hexagonal recess.

Each type of 1 2 ss bolt serves a unique purpose. Choosing the right one depends on the specific demands of your project. For example, if you’re working on a project involving wood, like a baseball bat display case, carriage bolts would be the optimal choice. Just like how different formations in football require different player positioning, different projects require different bolts.

Selecting the Right 1 2 ss Bolt for the Job

When choosing 1 2 ss bolts, consider the following factors:

- Material: Stainless steel offers excellent corrosion resistance, but different grades exist. 304 stainless steel is common for general use, while 316 is preferred for marine and chemical environments.

- Thread Pitch: This refers to the distance between threads. Ensure the bolt’s thread pitch matches the nut or threaded hole it will be used with.

- Length: Measure the thickness of the materials being fastened and choose a bolt long enough to pass through them and engage the nut fully.

- Head Type: As discussed earlier, different head types are suited for different applications. Select the head type that provides the best access and functionality for your project.

- Strength Requirements: For heavy-duty applications, ensure the bolt’s tensile strength meets the project’s demands. Just like I need strong legs to control the midfield, your projects need strong bolts to hold everything together.

Best practices for installing 1/2" stainless steel bolts

Best practices for installing 1/2" stainless steel bolts

It’s important to choose high-quality bolts. Imagine playing a match with a bolts baseball that’s not properly stitched. The consequences could be disastrous! Similarly, choosing subpar bolts can compromise the integrity of your project.

Installation Best Practices for 1 2 ss Bolts

Proper installation is crucial for maximizing the performance and longevity of your 1 2 ss bolts. Here are a few key tips:

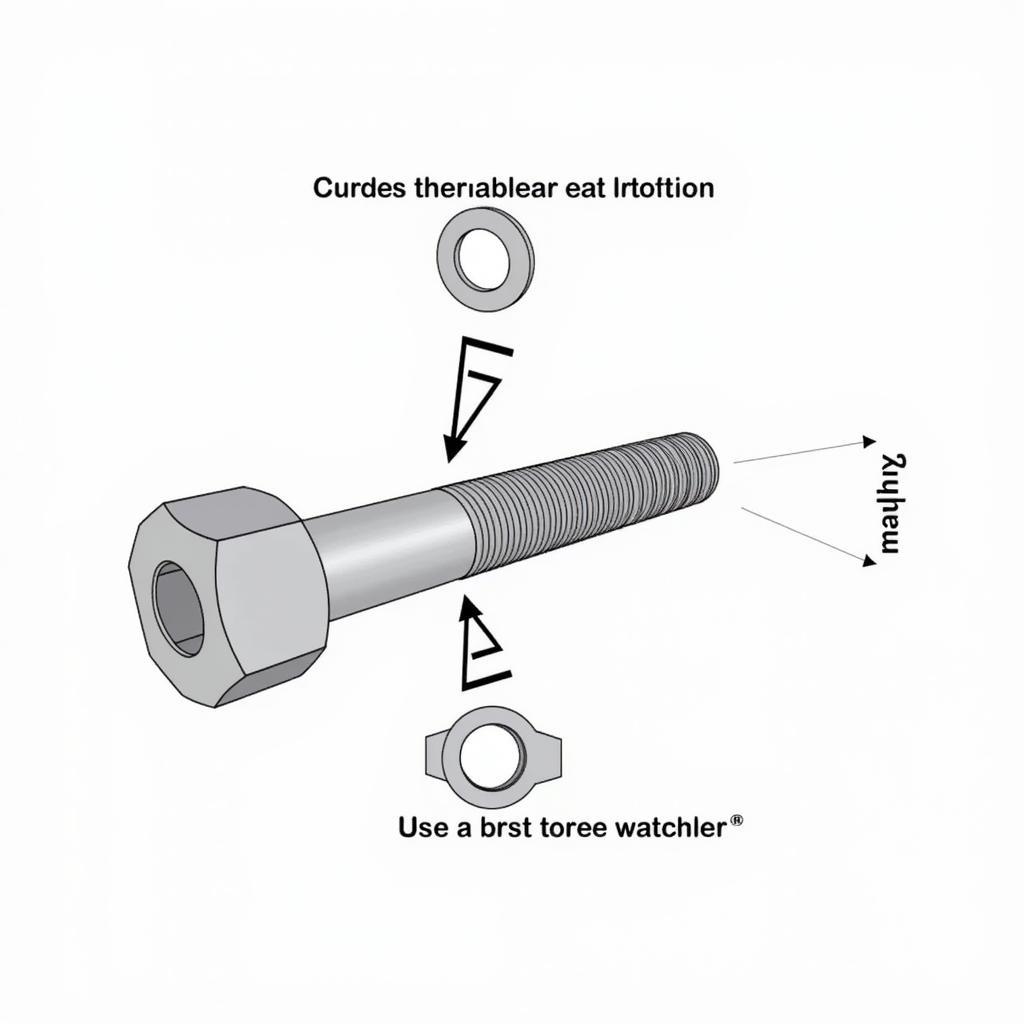

- Use Washers: Washers distribute the load and prevent damage to the materials being fastened.

- Torque Wrench: Use a torque wrench to tighten bolts to the correct specification. Over-tightening can damage the bolt or the materials, while under-tightening can lead to loosening.

- Anti-Seize Lubricant: Applying anti-seize lubricant to the threads can prevent galling and make future removal easier, especially in corrosive environments. Think of it like applying the right amount of spin on the ball – it ensures a smooth and controlled outcome.

Common problems encountered when working with 1/2" stainless steel bolts and their solutions

Common problems encountered when working with 1/2" stainless steel bolts and their solutions

Conclusion

Choosing the correct 1 2 ss bolts is paramount for any project. By understanding the different types, considering the specific requirements, and following best practices for installation, you can ensure a secure and long-lasting result. Just like a successful football game requires meticulous planning and execution, a successful project depends on the right tools and the right knowledge. If you have any questions or need assistance with your projects, our support team is here to help!

FAQ

- What is the difference between 304 and 316 stainless steel?

- How do I determine the correct length bolt for my project?

- What is the purpose of using a torque wrench?

- Can I use 1 2 ss bolts in a marine environment?

- Where can I find high-quality 1 2 ss bolts?

- What are the advantages of using sd bolts?

- How do I choose the right type of stainless steel bolt for my 2023 sprinter running boards?

Do you have any further questions? Explore our articles on cuna 4 en 1.

Need help? Contact us at Phone Number: 0963418788, Email: [email protected] Or visit us at: 2M4H+PMH, Nghĩa Thành Ward, Gia Nghĩa, Đắk Nông, Vietnam. We have a 24/7 customer service team.